- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

Automotive Industry

Lean Approach for Automotive Industry - High Efficiency and Productivity

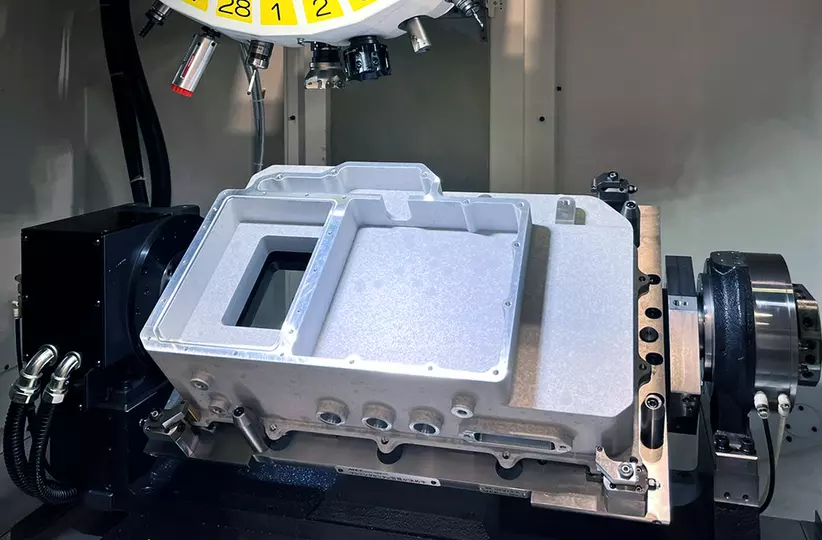

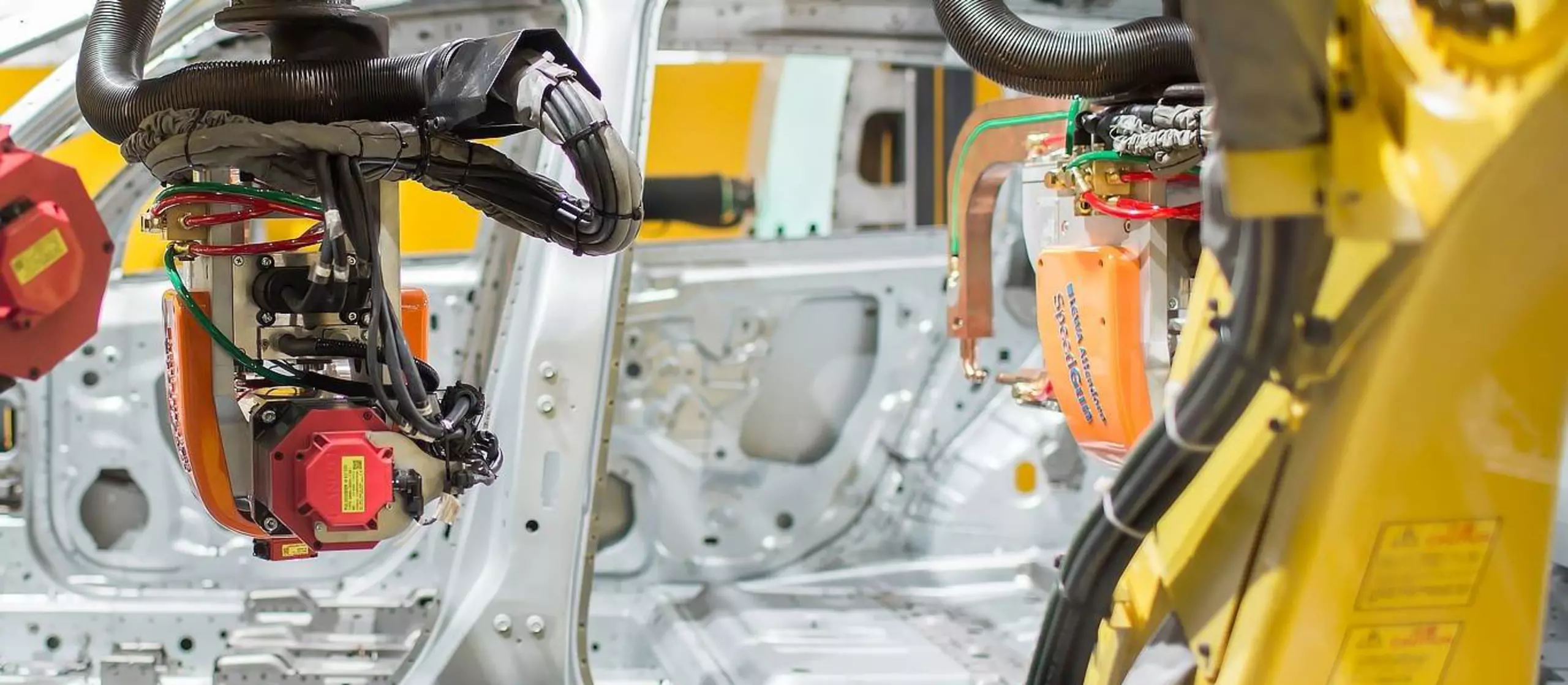

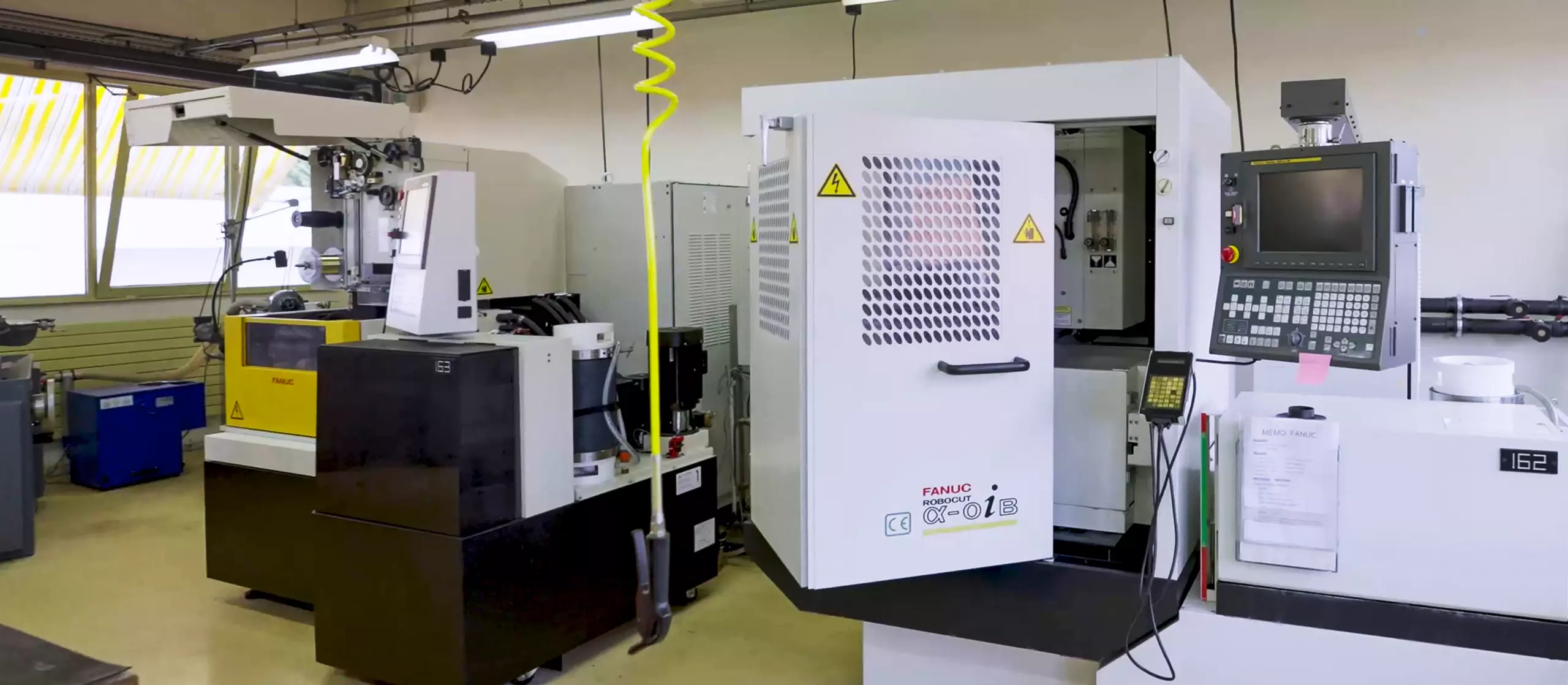

FANUC is a leading automation partner for the automotive industry, offering a wide range of solutions from industrial robots and CNC systems to drilling, wire-cut, and injection-moulding machines. Our technology supports complex machining and diverse manufacturing needs, enhancing efficiency and sustainability. With FANUC's energy-efficient innovations, automotive manufacturers and suppliers can stay competitive and eco-friendly. Our advanced technology optimises processes and boosts productivity, driving progress towards a sustainable automotive future.

Benefits for your Industry

Cost Reduction

Improved Quality Control

Enhanced Safety

Faster Production Rates

Increased Efficiency

Flexibility and Adaptability

Unsurpassed Precision

Dependable Reliability

FANUC Case Studies in the Automotive Industry

FANUC Solutions Provide Common Thread at Screw-Cutting Specialist

Moving from labour-based to automated production operations can sometimes appear daunting. And yet, with the right technology partner on-board, processes such as automated machining and assembly can come to realisation with relative ease, instantly delivering new levels of productivity and reliability.

FANUC ROBOSHOT Machines Keep Things Simple for SIMON

High-volume plastics parts; thin walls; zero defects; short automotive lead times; demanding energy efficiency requirements. A growing number of manufacturers are combatting these common challenges by investing in ROBOSHOT high-performance, all-electric injection moulding machines from FANUC. Among their number is SIMON Plastics.

FANUC Provides the Missing Link at ZPM

When ZPM wanted to increase its machine and robot utilisation, support the company’s vertically integrated manufacturing strategy and map its output more precisely, it turned to FANUC’s MT-LINK𝑖. With this advanced software, manufacturers like ZPM can supervise and manage data from one to 2,000 machines, robots and PLC systems.

System Integrator Finds the Perfect Partner in FANUC

Sometimes a long-standing and business-critical working relationship develops almost by chance. In this case, when a major customer expressed a preference for FANUC robots, leading UK system integrator ALS Mechatronic was prompted away from its existing robot suppliers. Five years later, the company is truly glad about the situation, as FANUC and ALS Mechatronic have established a highly fruitful and rewarding business partnership that today benefits a broad spread of the company’s end users all around the world.