- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

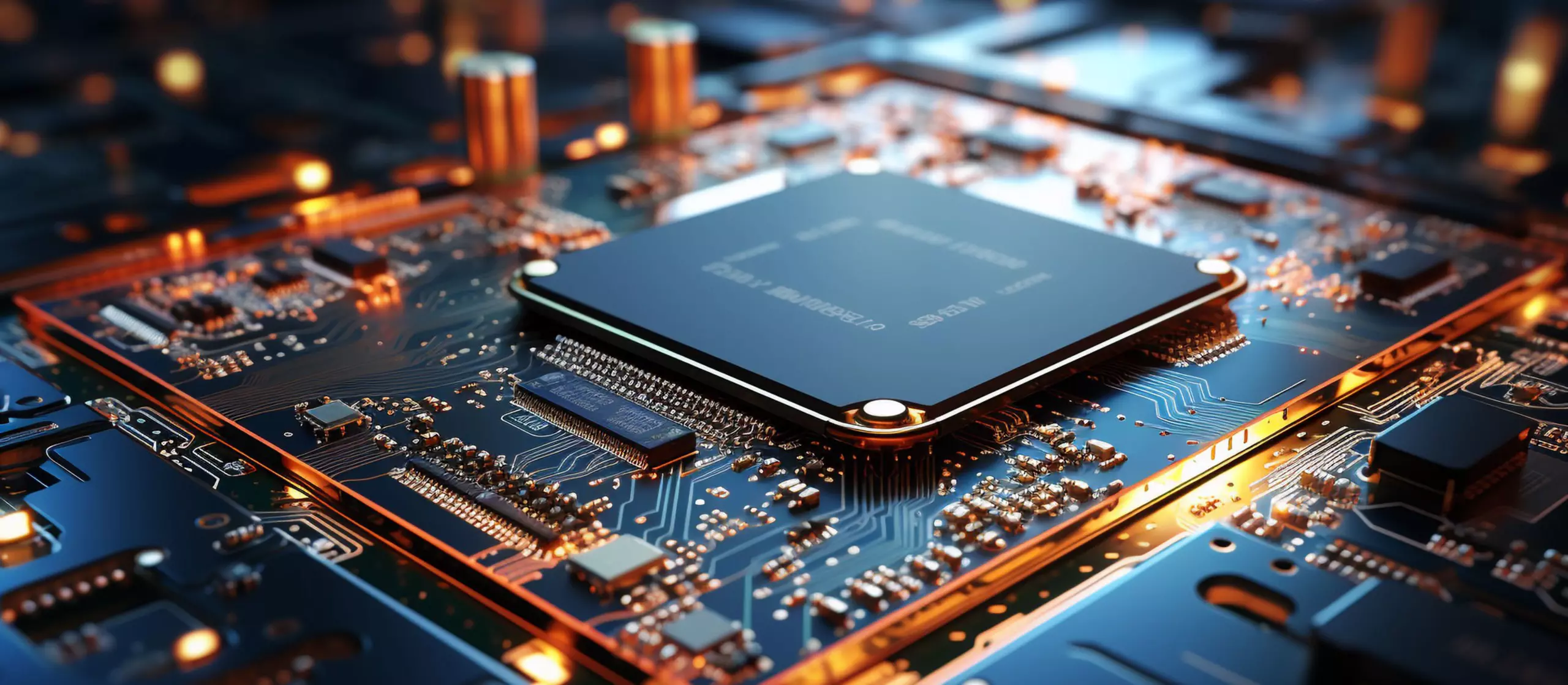

Electronics

Higher Productivity all Along Your Value Chain

In the fast-paced, competitive electronics industry, the ability to combine consistently high standards of quality and precision with maximised productivity, low production costs and fast process times is essential. Offering huge flexibility across a vast range of manufacturing processes, automated solutions make achieving this synthesis relatively easy. FANUC machines have been designed to deliver extremely repeatable precision, rock-solid reliability and create efficiencies that significantly drive down your costs. What is more, they provide you with the flexibility to respond dynamically to market trends and demands. Whether you want to automate your entire production scenario or just a small part of it, FANUC has a solution that is not only suited to your needs but will also help to future proof your business.

- Application

- Related products

- Benefits

Robotics & Automation for the Electronics Industry

Boost electronics manufacturing efficiency with FANUC’s automated solutions, offering precision, reliability, and dynamic market responsiveness.

Assembly

Picking & Placing

Soldering

End-of-the-line automation

Injection moulding

Wire EDM cutting

High-accurate drilling

Complex Machining

Hard Turning

Milling

Laser, Plasma and Waterjet cutting

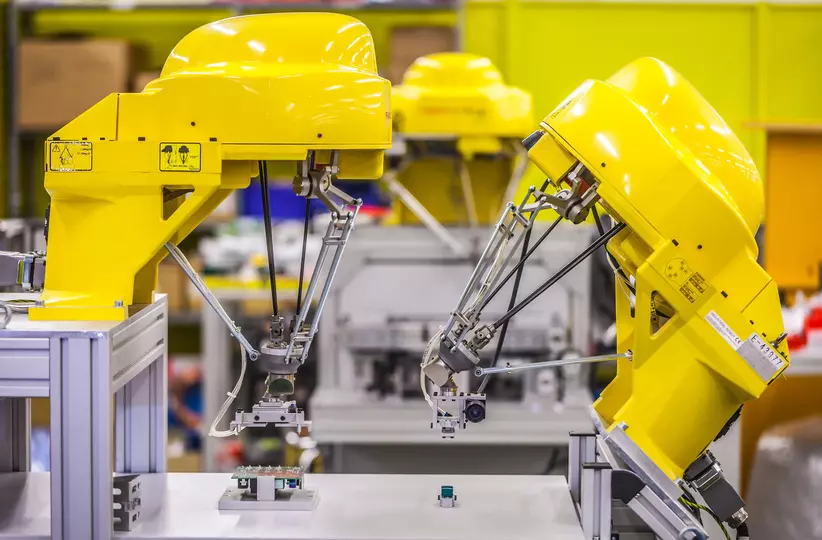

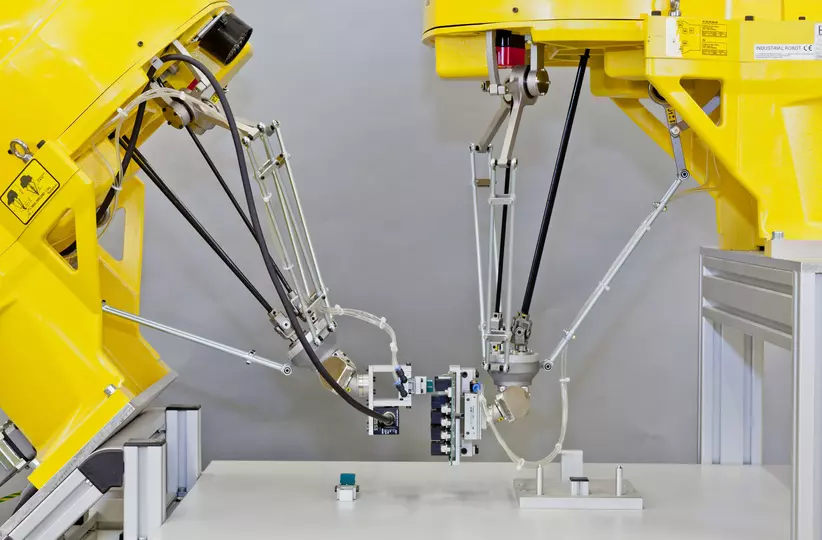

Assembly

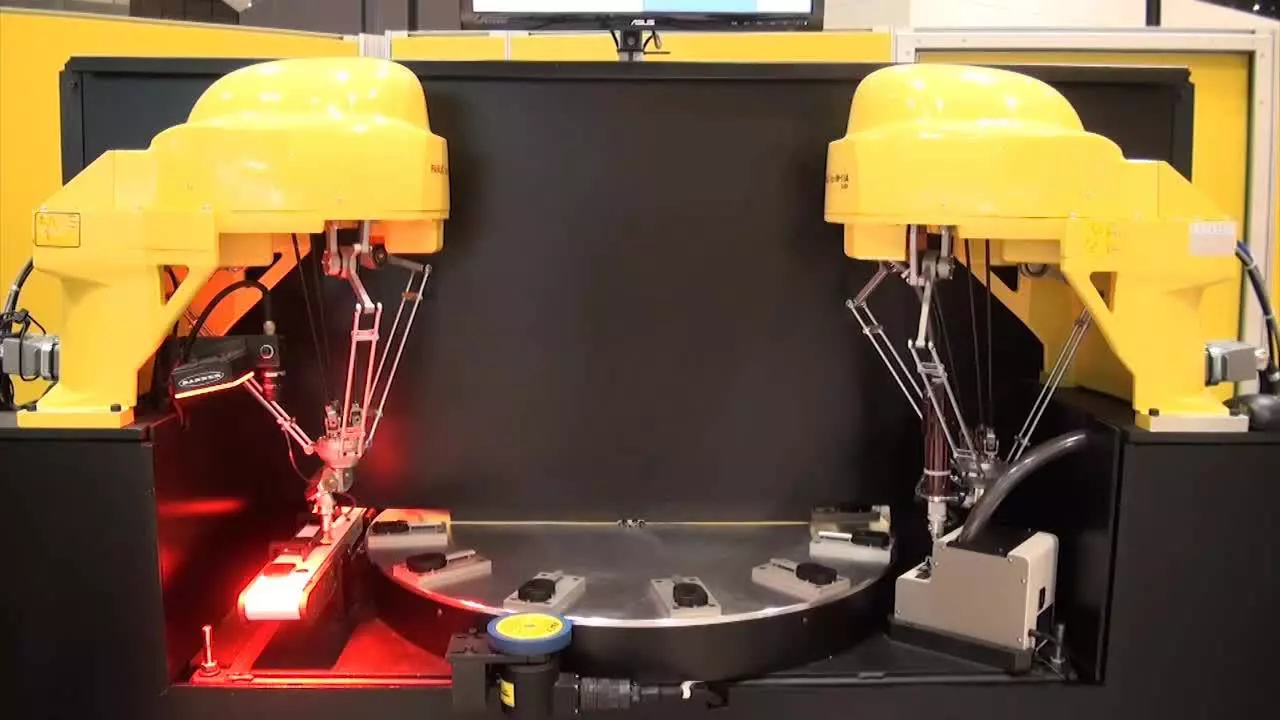

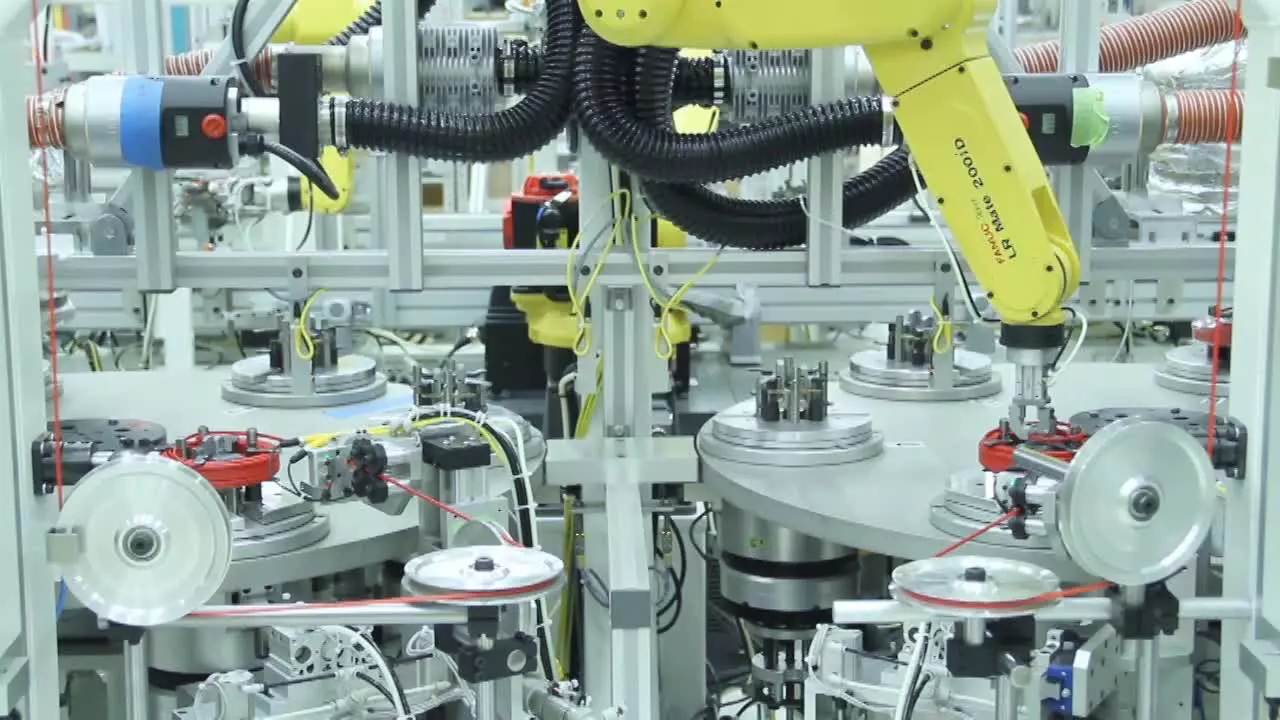

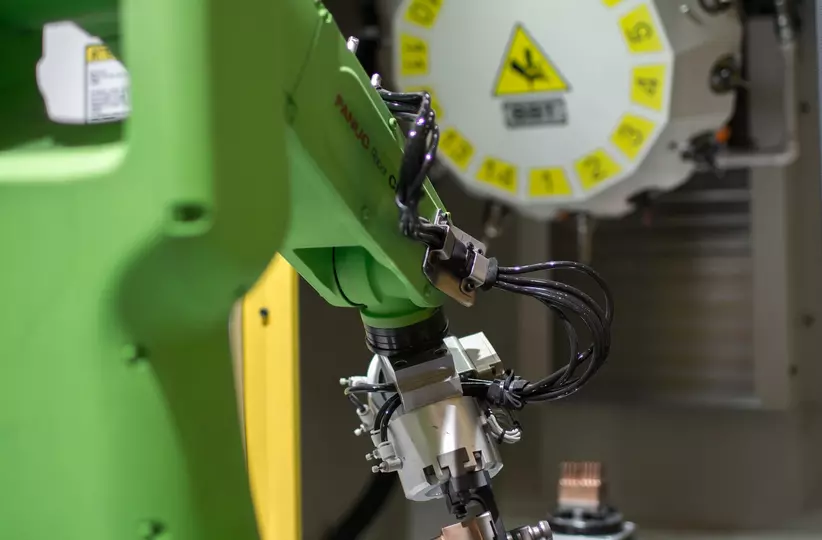

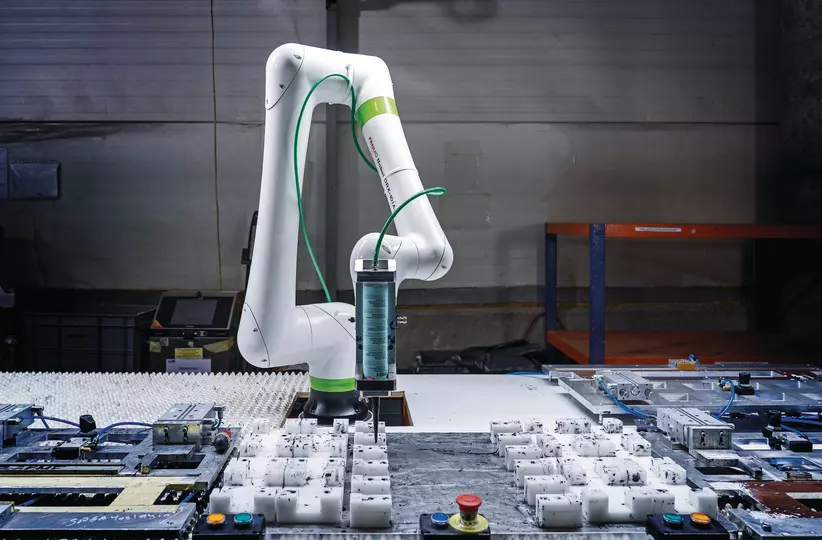

FANUC offers a variety of highly reliable assembly robots that are dexterous, repeatable, compact and fast. From 5 to 6 axis articulated robots, to 3-6 axis Delta robots to our SCARA Series and Collaborative Robots, we’ve got robots and the intelligent features needed to keep your production goals on track.

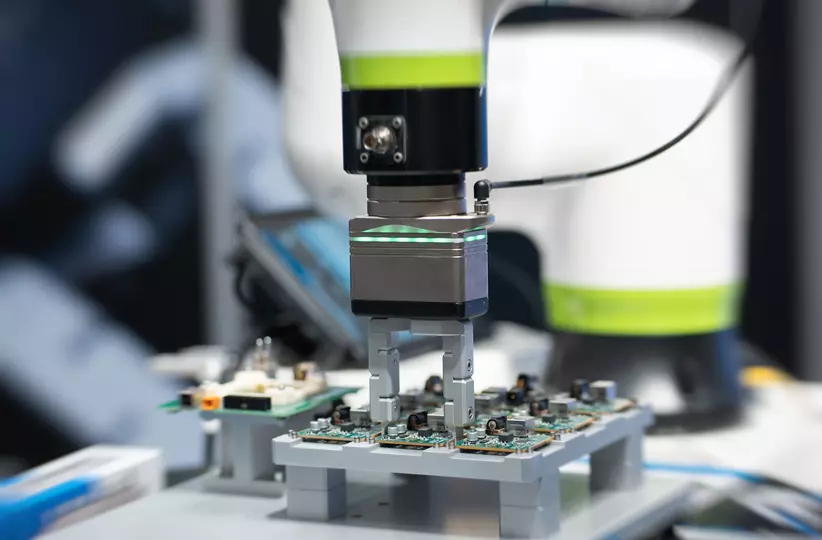

Picking & Placing

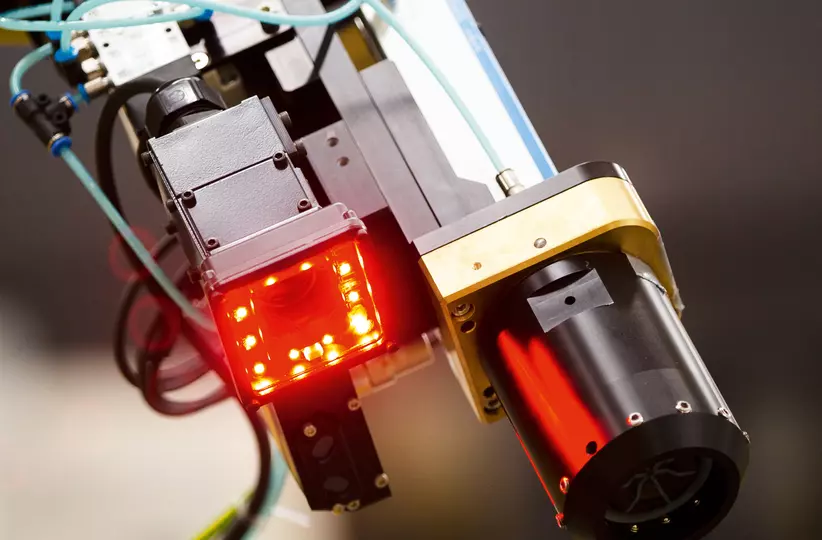

Equipped with 𝑖RVision and 3D Area Sensor, FANUC robots pick, sort, place and arrange products on a moving conveyor. For example delta robots are the perfect choice for picking, sorting, inspecting, placing and inserting parts. This can be done at high speed on moving conveyors.

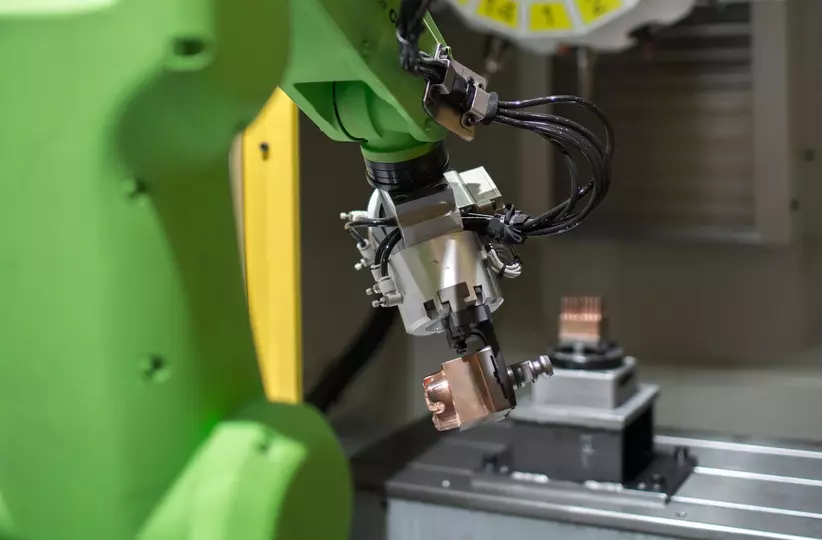

Soldering

Robots utilised for soldering and welding tasks ensure consistent and accurate application of solder or welding material, contributing to the quality and reliability of electronic products.

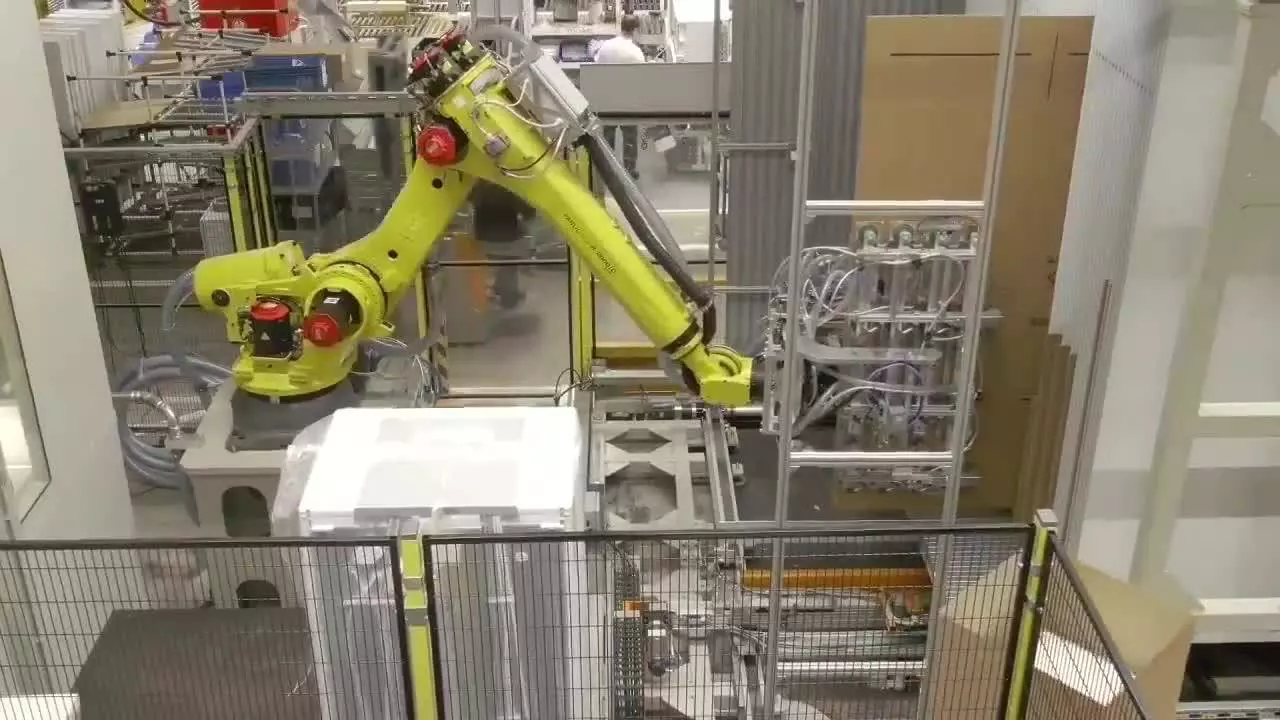

End-of-the-Line Automation

Get your products sorted for delivery with our robots equipped with a vision system. Automating end-of-line processes, such as wrapping, labelling, packing and palletising, streamlines the packaging process and enhances overall logistics efficiency.

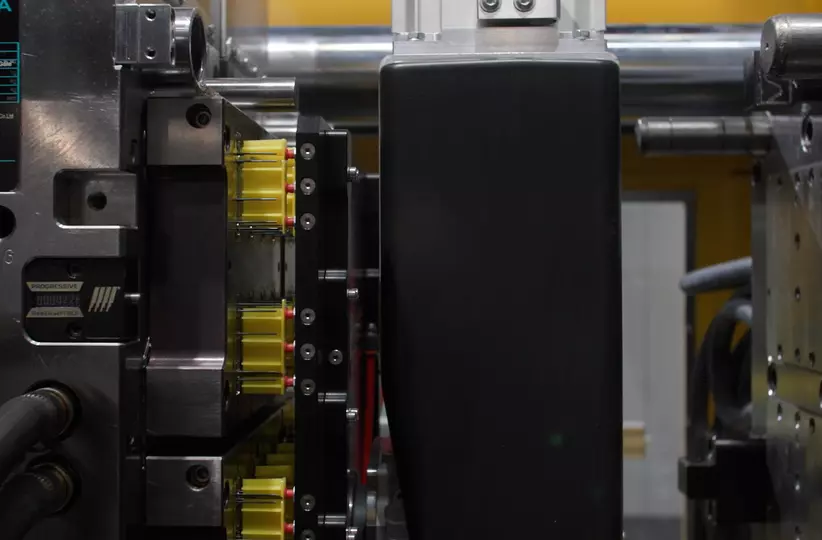

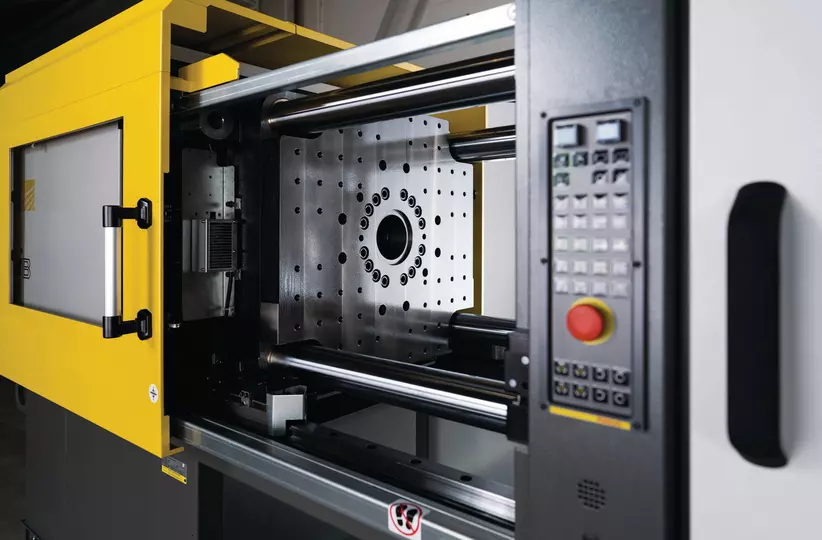

Injection Moulding

Producing high numbers of small electrical components requires speed and repeatability. The acceleration delivered by ROBOSHOT’s electric servomotors is ideal for creating the thin walls that electrical parts often demand. Moreover, ROBOSHOT smart functions compensate for viscosity changes, while active gas venting further enhances quality.

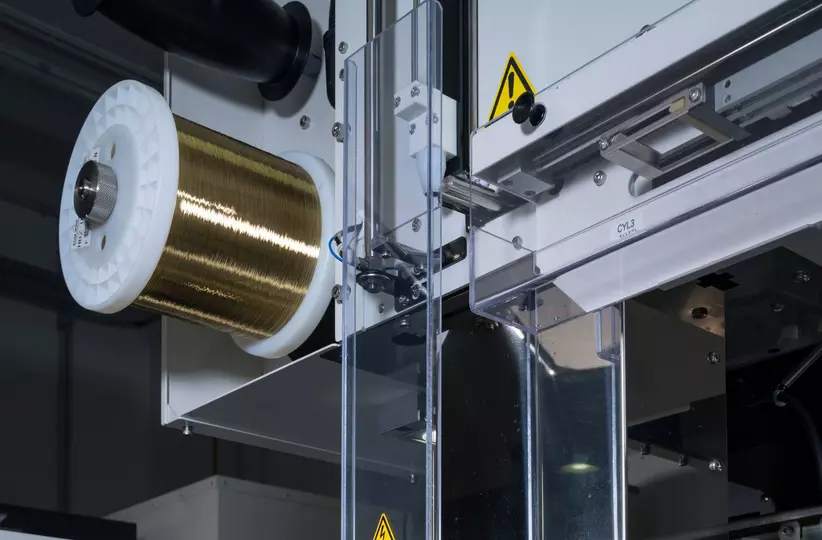

Wire EDM Cutting

With its extensive range of options ensuring pristine surfaces and incredible accuracy of parts, ROBOCUT stands out as the perfect all-rounder for the electronics industry. FANUC’s wire EDM demonstrates extremely high accuracy on tooling, such as molds. The machine's incredible levels of repeatability further guarantee that the same high standards are consistently obtained.

High-Accurate Drilling

Electrical industry applications often require tiny holes drilled in precision components. To do this, FANUC ROBODRILL comes with a finely balanced spindle to ensure a very high degree of repeatable accuracy. To maximise precision on applications of this kind, ROBODRILL also includes a tool cleaning unit. Cleaning both the tool and spindle during tool changes, this feature vastly improves repeatability.

Complex Machining

FANUC CNCs allow you to achieve high production output and the highest quality standards for fast and precise 5-axis milling, turning, grinding or cutting of complex parts housings of all kinds, from consumer to aerospace electronics. FANUC's ROBODRILL offers simultaneous control and advanced features like look-ahead, interpolation, and smart smoothing functions for precise, quick production of complex moulds, electrodes, and 3D parts.

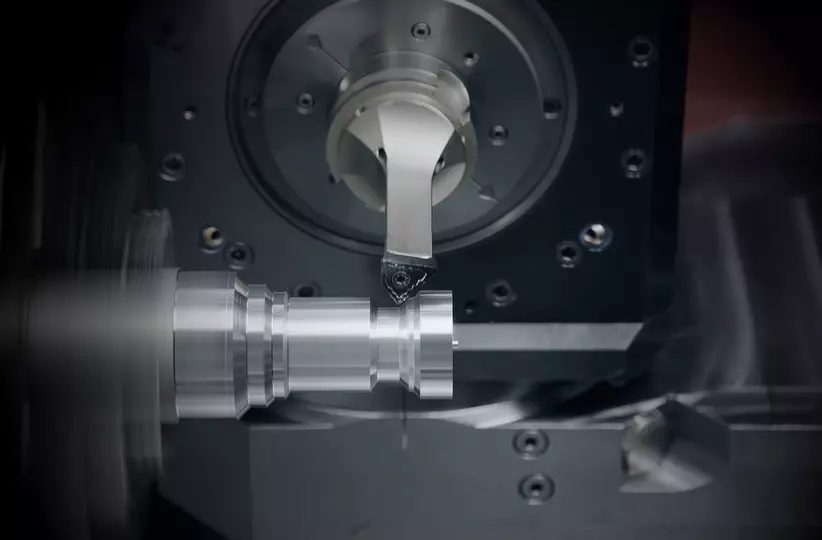

Hard Turning

For the production of electrical and electronical components, fast ultra-precise hard turning technology using FANUC drives and controls is an economical alternative to circular grinding and achieves accuracies in the micron range.

Milling

FANUC enhances electronic components milling with the ROBODRILL center and machine robotisation for top efficiency. Our CNC control ensures easy operation and superior results across a wide range of applications.

Laser, Plasma and Waterjet Cutting

FANUC's advanced CNC controllers (30/31𝑖-LB Plus, 0𝑖-LF Plus) lead the way in laser, plasma, and waterjet cutting applications, offering unmatched precision and efficiency. Coupled with robotisation, FANUC elevates these cutting processes, ensuring superior quality and speed in the most demanding manufacturing environments.

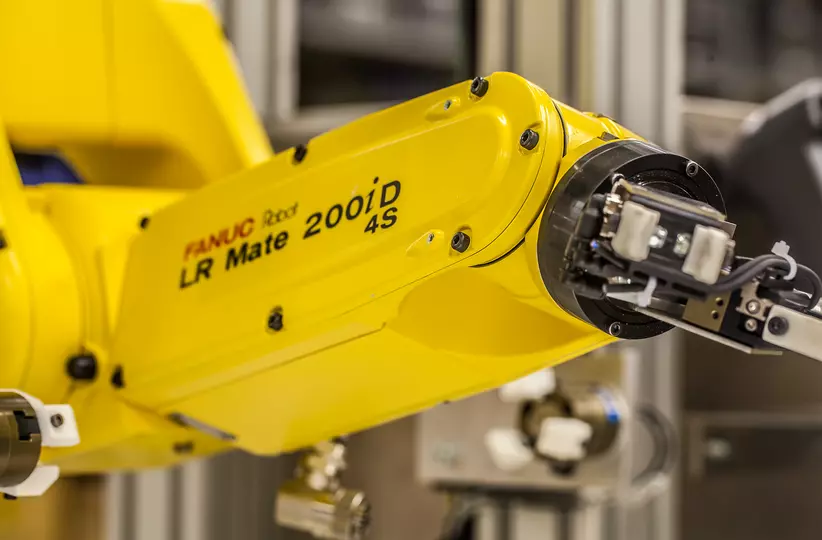

Our Robot Offer

SCARA Series

Delta Series

LR Mate Series

Cleanroom Robots

Collaborative Robots

Our Machining Offer

ROBODRILL

ROBOSHOT

Highlights

High-Quality Surface Finish

In-House Servo Technology for High Accuracy

Cleanroom Robots

Collaborative Robots

𝑖RVision

Benefits for your Industry

Precision and Accuracy

High Speed and Efficiency

Versatility

Reliability and Durability

Ease of Integration

Programming Flexibility

Compact Footprint

Energy Efficiency

Quality Control

Lifecycle Support

Our Solutions for Other Industries

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.