- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

Food & Beverage

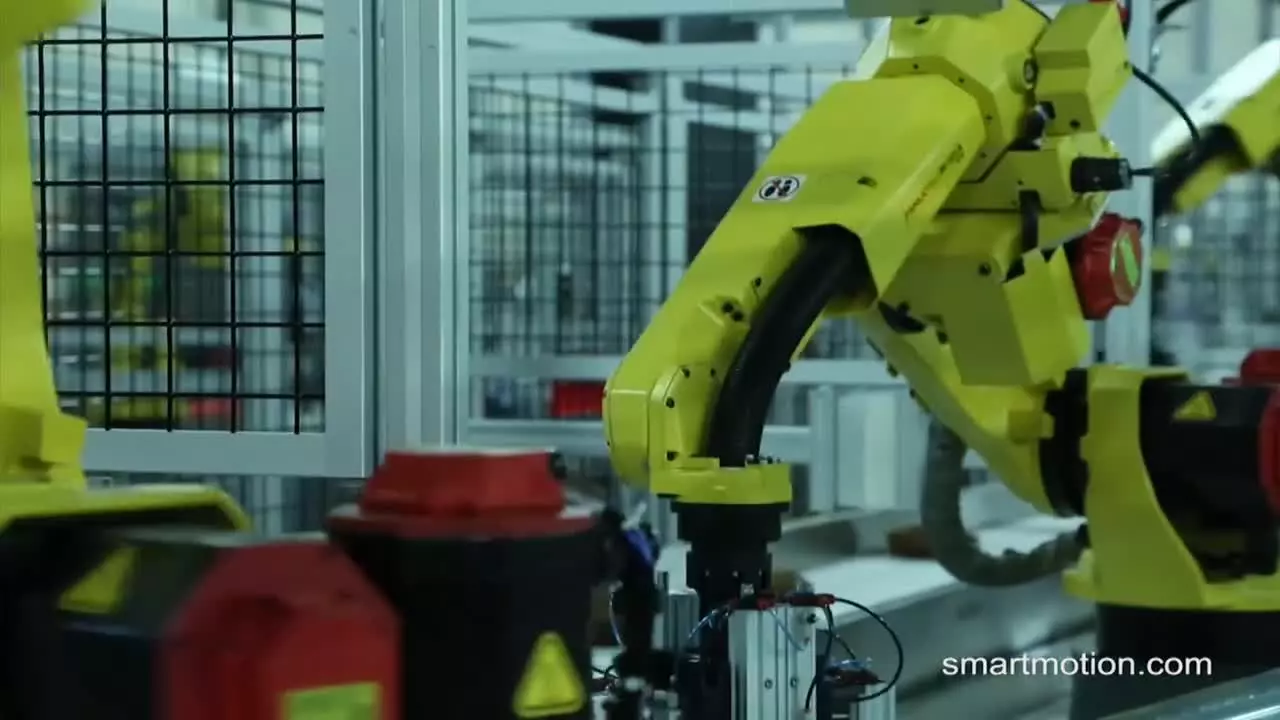

Dedicated Robot Solutions to Make Your Factory Process More Efficient

Automating your food or beverages production facilities is easier than you might think. Specifically for food processing automation delivers consistently better quality, improves picking and handling times and increases output by speeding up packaging processes. The net results are lower costs and greater competitive scope. What is more, intelligent specialised automation also allows you to respond flexibly to today’s competitive market dynamics and the ever-changing demands of the food manufacturing industry.

No matter what your factory process, we're focussed on helping you come up with the best solution to improve your productivity. By sharing our knowledge of production processes and automated solutions, we'll show you what's possible and where you can improve.

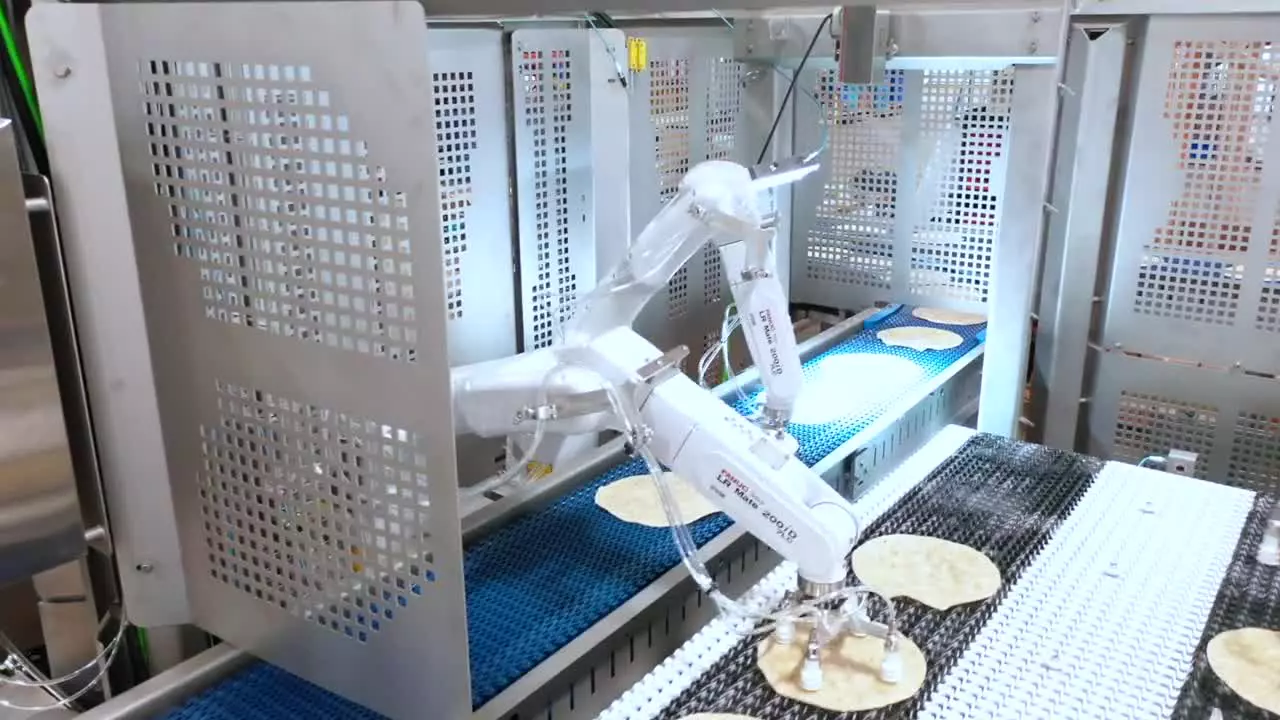

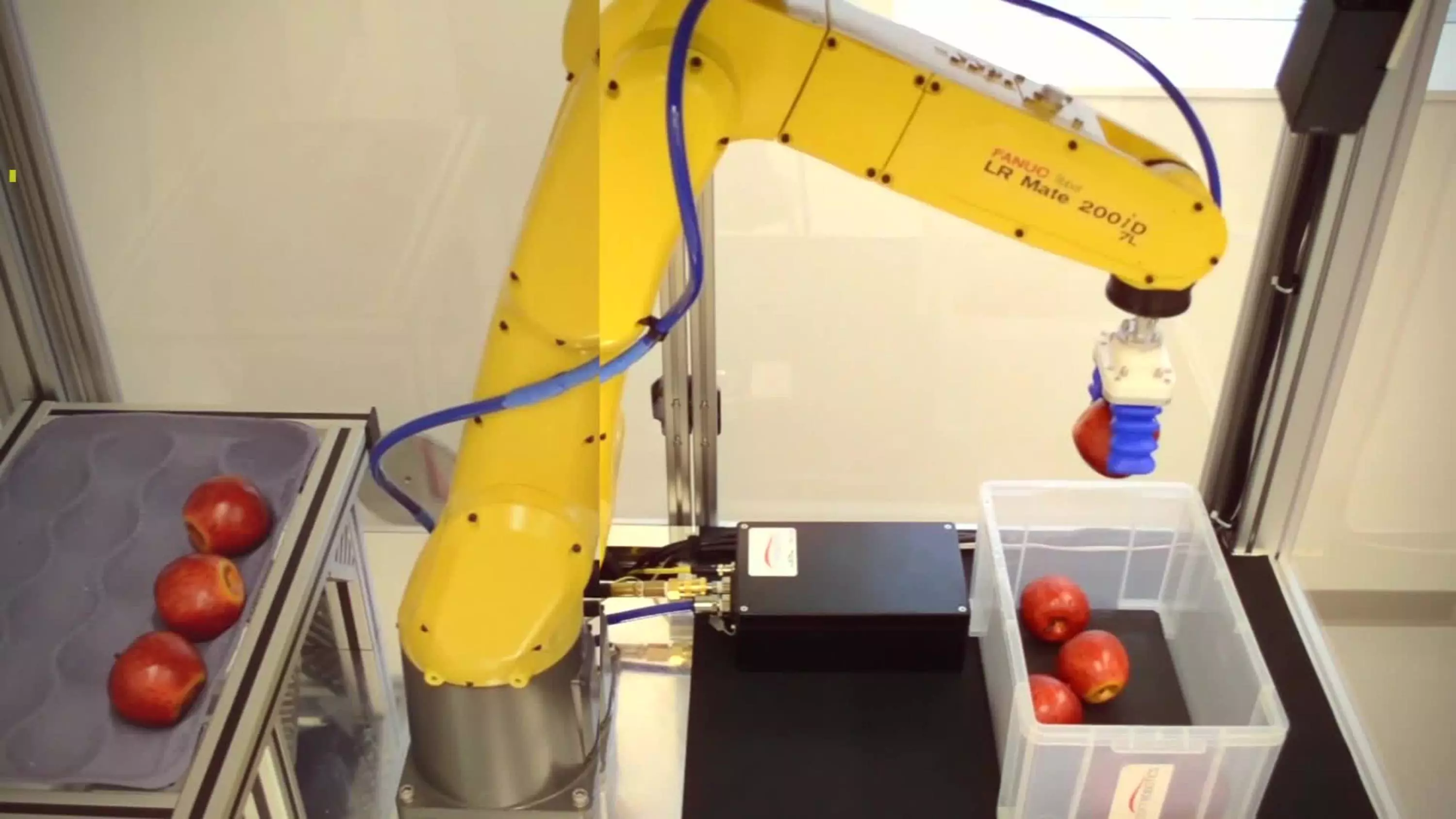

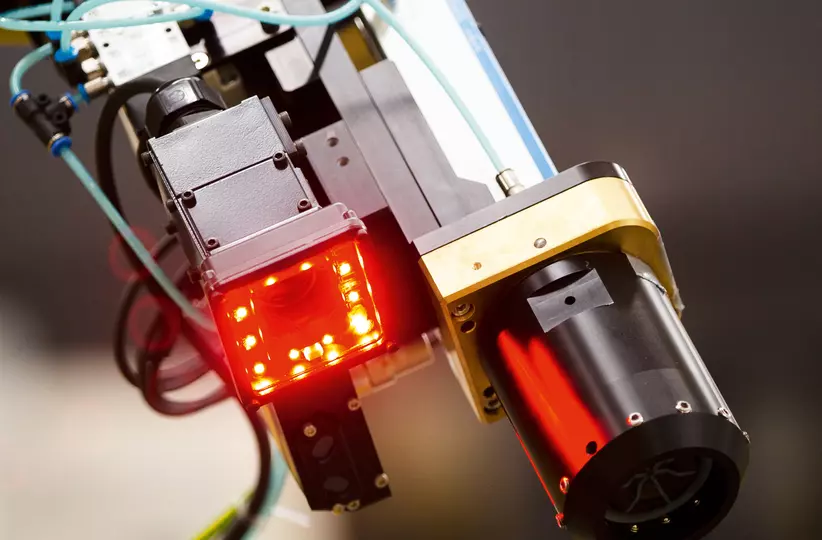

Robots for Primary Food Processing & Handling

Food safety is key when it comes to primary food handling. That’s why FANUC has designed food-grade robots equipped with food-grade grease and special finishes and features perfect for these applications. FANUC’s food-grade robots are designed to help mitigate the risk of any food safety issue and can withstand frequent and rigorous washdowns while maximising speed and versatility in primary food processing. These robots range from 550mm - 1853mm in reach and include both IP67 and IP69K rated models. Explore our food-grade robot models below.

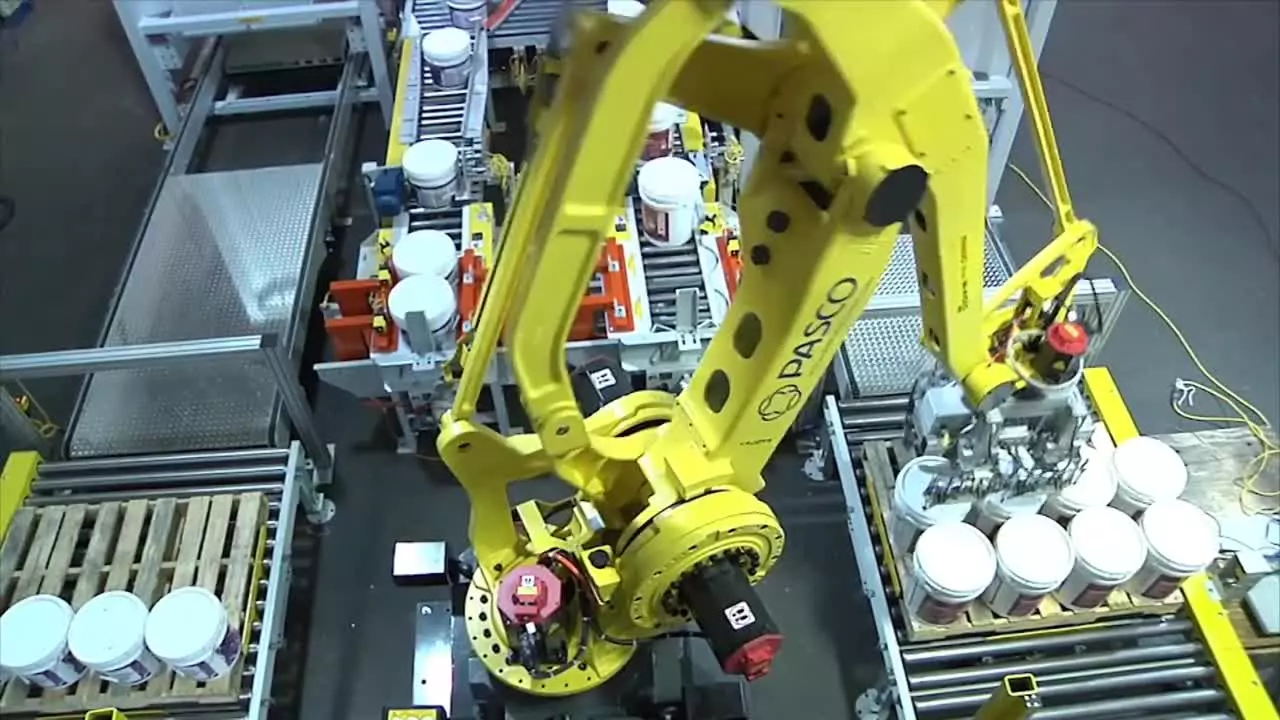

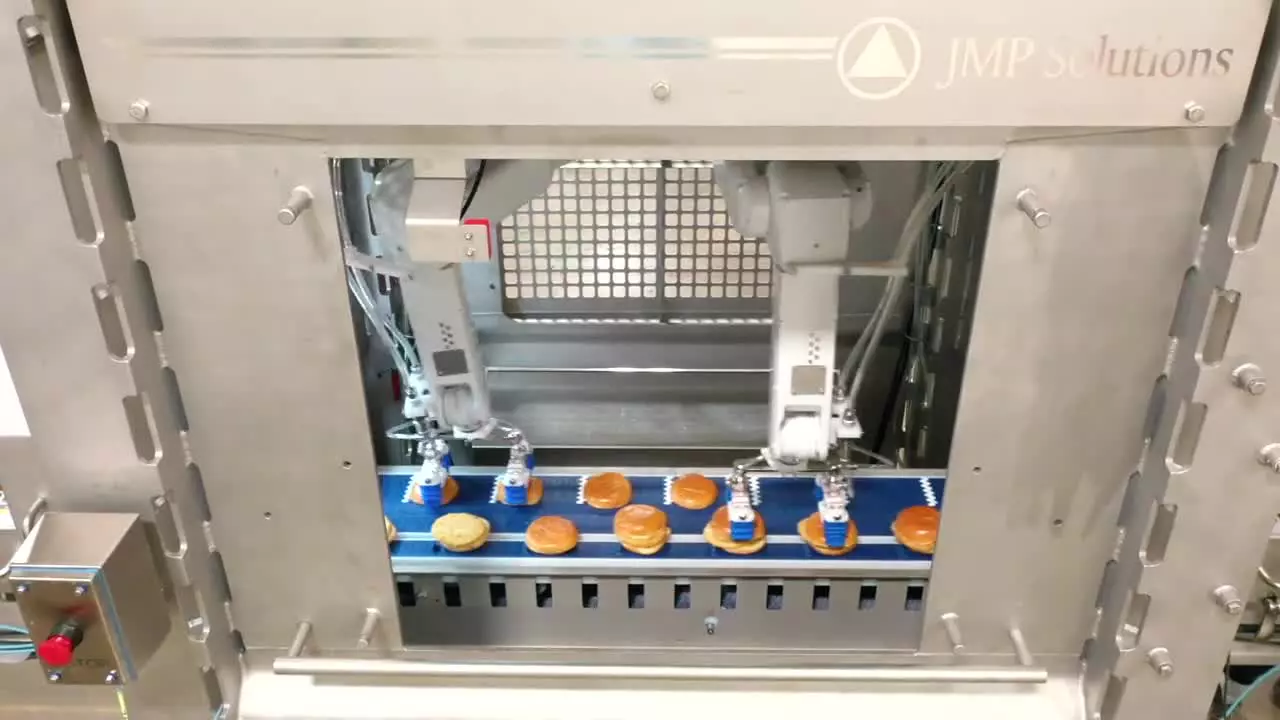

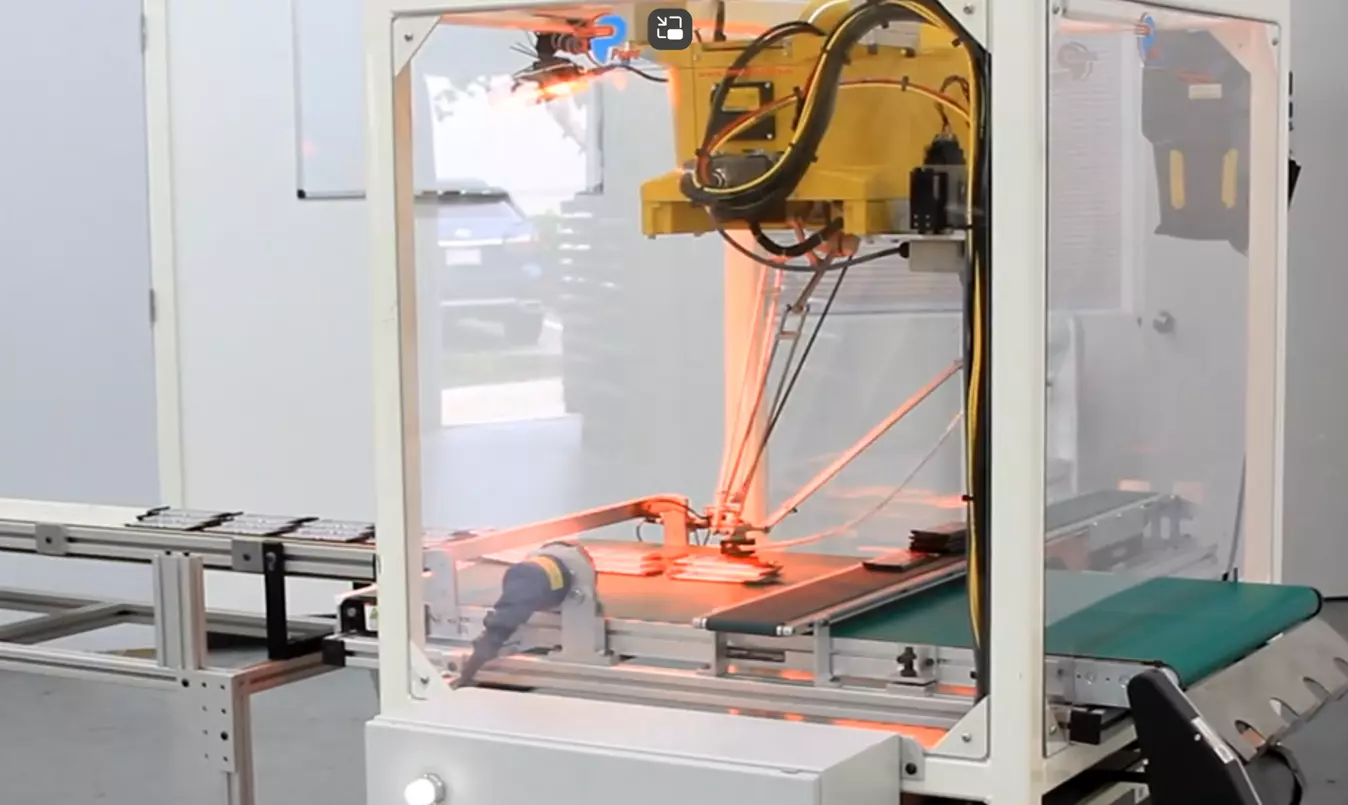

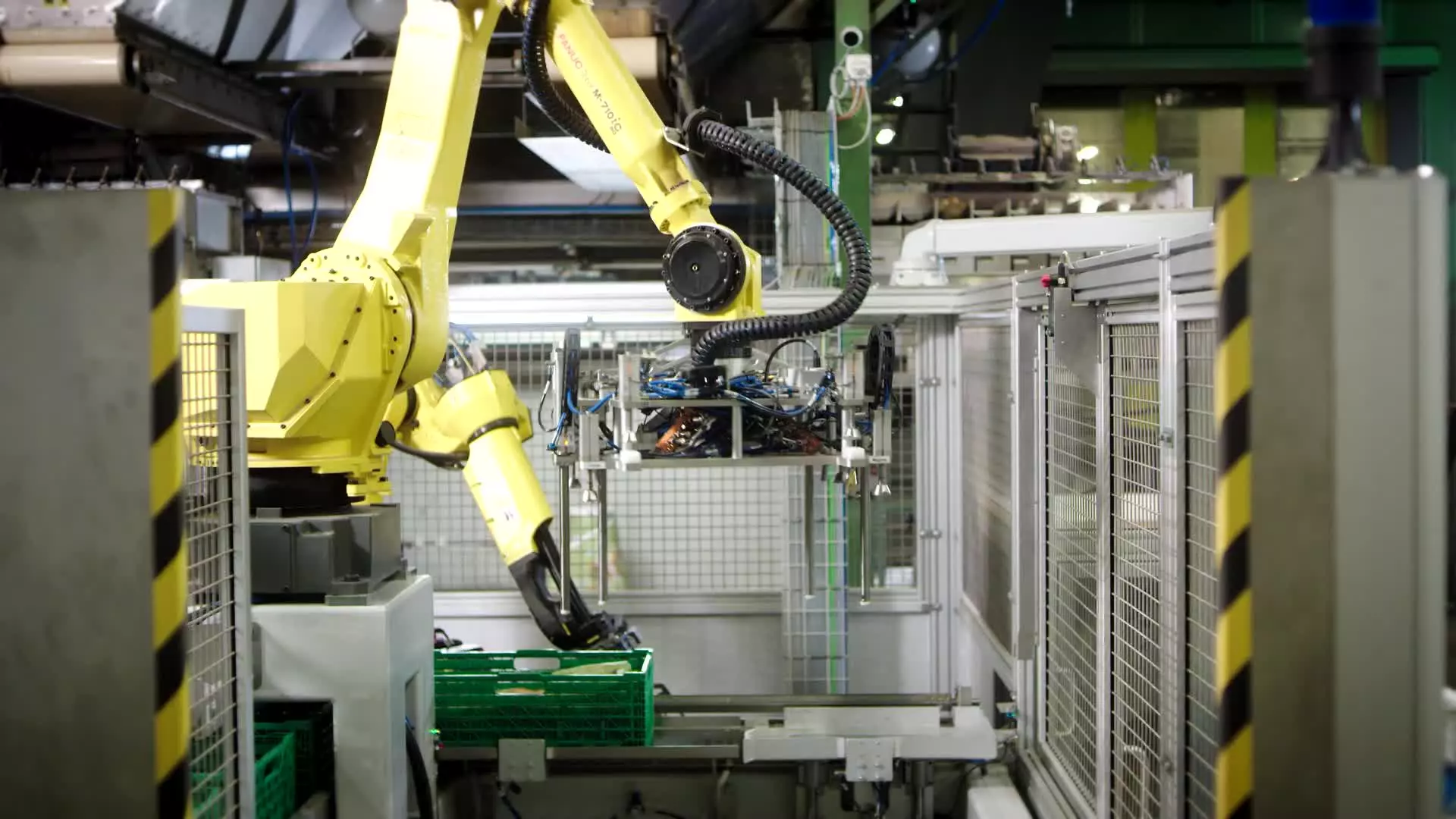

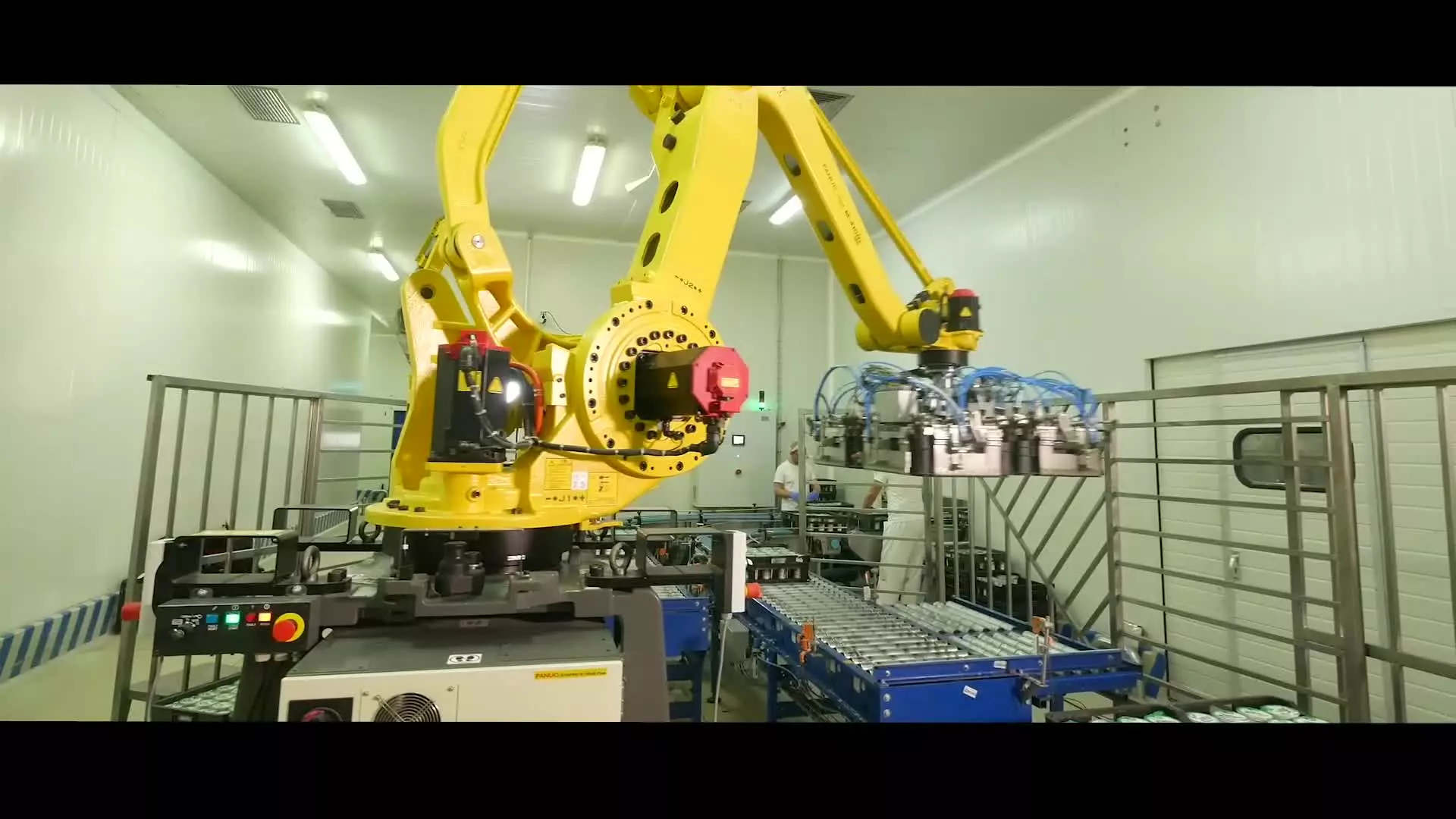

Robots for Secondary Food & Beverage Handling

Automating secondary food and beverage processing and packaging helps optimise your production by ramping up throughput while overcoming labor challenges. Whether it’s palletising or picking and packing – FANUC has robot and cobot solutions to automate many manual tasks enabling your food manufacturing operations to stay nimble and competitive. Discover some of the ready-to-order variants from the wide range of robot families.

Our Solutions for Other Industries

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.