IMPORTANT INFORMATION

All FANUC entities have suspended their shipments to Russia and Belarus, and service and maintenance for our installed products are not provided within those countries.

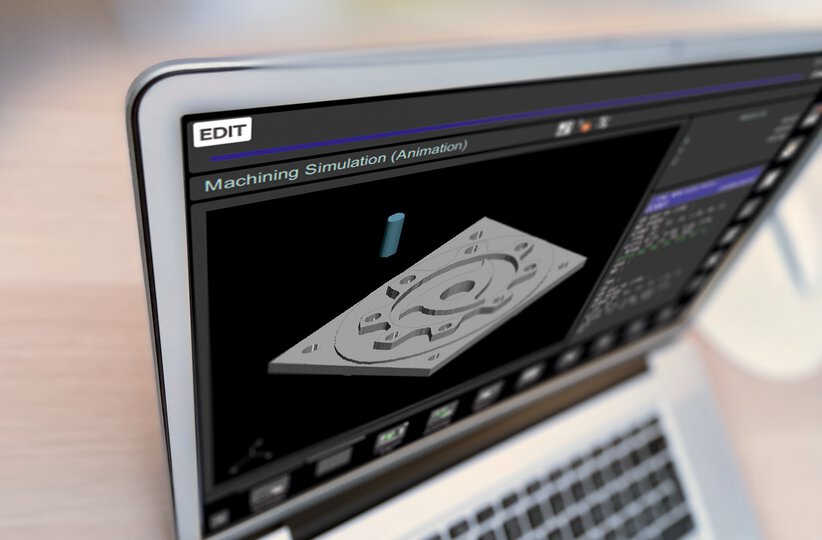

CNC GUIDE 2

Share

Enhance operational efficiency, streamline training, and drastically reduce downtime with the pioneering next generation of CNC simulation.

Incorporating our CNC GUIDE 2 into your manufacturing ecosystem delivers measurable benefits. By simulating and enhancing processes before execution, you not only save resources but also elevate your product quality, surpassing client expectations. FANUC CNC GUIDE 2 stands as your ally in achieving unmatched operational excellence and sustainable growth.

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT