ROBODRILL Preventive Maintenance

Share

Preventive maintenance is crucial for ensuring the optimal performance and longevity of your ROBODRILL CNC machine. By adhering to a proactive maintenance schedule, you can minimise downtime and enhance productivity. Here, we provide an overview of what preventive maintenance entails, highlighting key areas of focus and benefits.

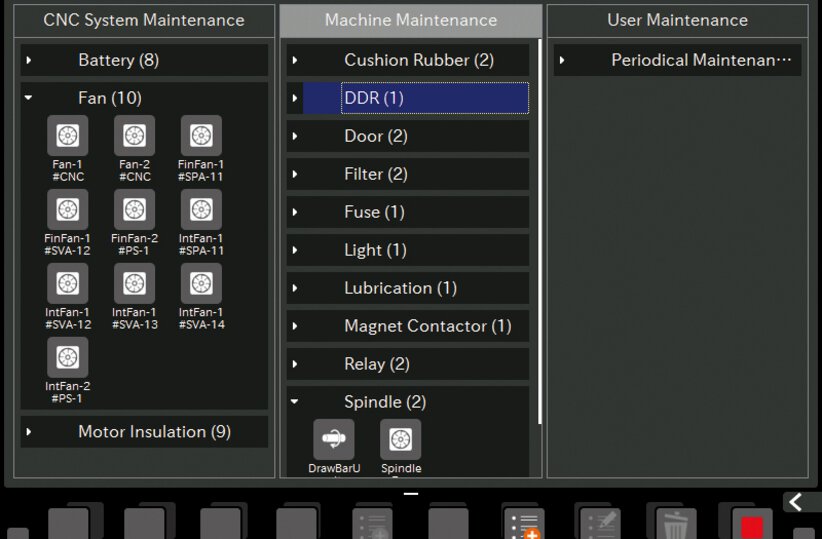

ROBODRILL will notify users when maintenance is required via its intuitive maintenance interface. Users can even add custom preventative maintenance reminders. This ensures that your machine remains in optimal condition, ready to meet the demands of your production processes.

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT