IMPORTANT INFORMATION

All FANUC entities have suspended their shipments to Russia and Belarus, and service and maintenance for our installed products are not provided within those countries.

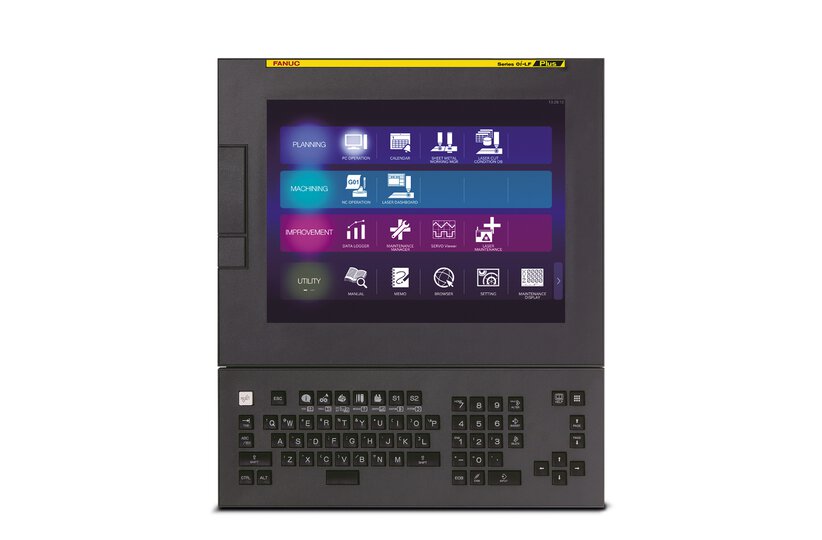

0𝑖-LF Plus

Share

Experience a commitment to precision and control that is specifically designed to increase your laser cutting productivity, exclusively for 2D laser cutting. At the heart of the FANUC 0𝑖-LF Plus are robust performance features that integrate seamlessly with a wide range of laser cutting machines to deliver flawless results. Whether your operations involve intricate cutting, engraving or other laser applications, this system ensures optimal productivity with fast processing speed and precision. Experience streamlined laser cutting with 𝑖HMI visualisation and proven FANUC reliability. Take your 2D laser cutting to the next level

Max. controlled axes total / per path

9 / 7

Max. spindle axes total / per path

4/3

Max. controlled paths

2

Get Inspired

Get Inspiration from Other's Success

Dener Group

FANUC Solutions Help Machine Builder Achieve International Success

Most machine builders know that gaining greater market share requires the development of strong supplier relationships based on trust. Turkey-based Dener Group is a case in point, where the adoption of FANUC CNC systems, spindle motors, servo amplifiers and power supply modules has seen the company emerge as a major player in the national and in...

Tailored Solutions for Your Industry

Complex Machining for the Aerospace Industry

Optimise Aerospace Manufacturing Processes with FANUC’s State-of-the-Art Complex Machining Solutions!

Complex Machining for the Automotive Industry

Precision and Efficiency in Automotive Manufacturing!

Complex Machining for the Medical industry

Medical Manufacturing Excellence with FANUC's Technology!

Electric Vehicles

No one has more experience automating electric vehicle production than FANUC. Trust us to help automate all of your EV manufacturing processes.

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT