- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

Unique Method Kft

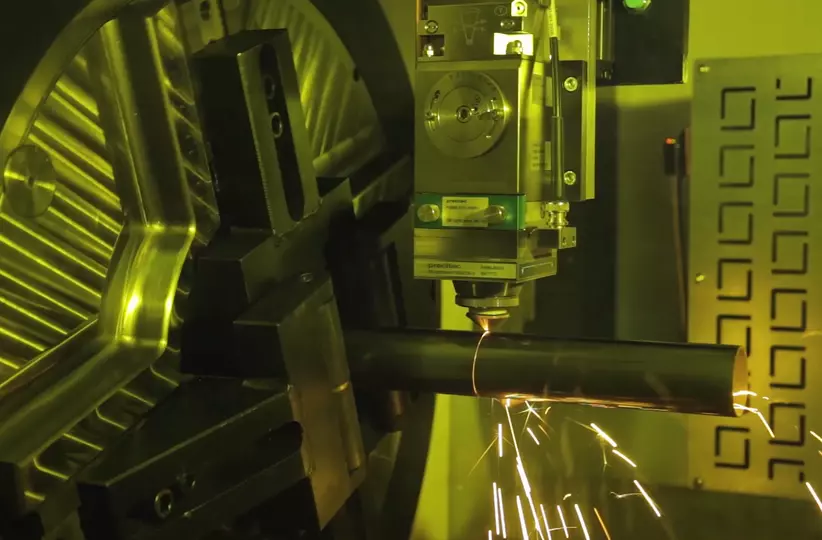

FANUC CNC Helps Turn Pipe Dream Into Reality

Any builder of custom machinery will say that choosing the right control system is paramount to project success. And when the machine in question has multiple axes that require simultaneous control at high speeds with ultra-precise accuracy, FANUC has the optimal CNC solutions available. Unique Method, a Hungary-based builder of custom laser cutting machinery, is among a growing number that have discovered this fact for themselves.

FANUC’s 31𝑖-L Model B CNC system is at the heart of the UMET UniTume 6000, an advanced laser pipe-cutting machine.

Implementing FANUC's CNC helped to shorten cutting times by half.

FANUC's reliable spare parts and technical support.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

All Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.

All Industries

Explore our comprehensive range of factory automation solutions, designed to optimise and streamline any manufacturing process.