- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

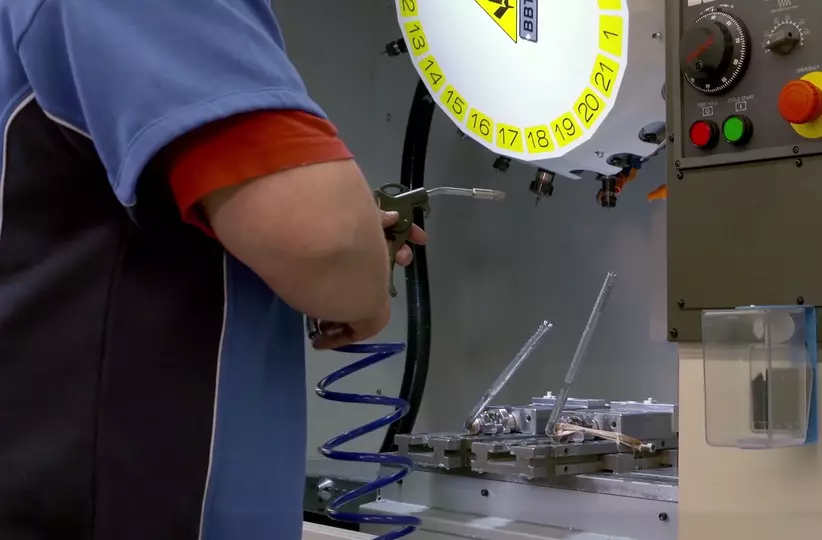

Vedos

Vedos Achieves Precision with FANUC ROBODRILL

When it comes to finding the right balance between high-precision, efficiency and cost, precision component manufacturer Vedos relies on FANUC’s ROBODRILL milling centers.

ROBODRILL milling centres rotate at 24,000 rpm to achieve high cutting speed.

Very stable and accurate machine that enables quick changeover.

Small components are produced with a high degree of precision.

Off-line programming and quality control.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

CNC Milling

CNC milling is a machining process that uses computer-controlled rotating cutting tools to remove material from a workpiece to create a desired shape. It is widely used for producing precision parts with complex geometries. The process involves securing the workpiece on a movable table and using various tools to cut, drill, and shape the material based on programmed instructions.

All Industries

Explore our comprehensive range of factory automation solutions, designed to optimise and streamline any manufacturing process.