- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

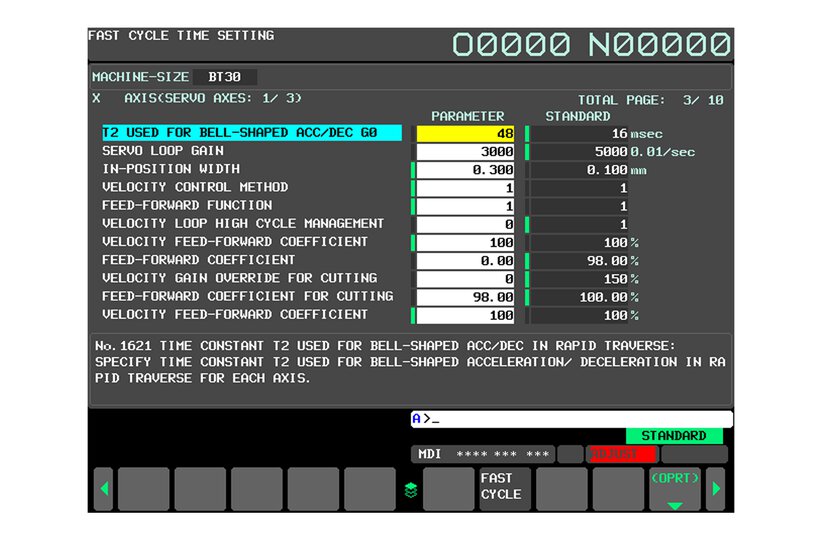

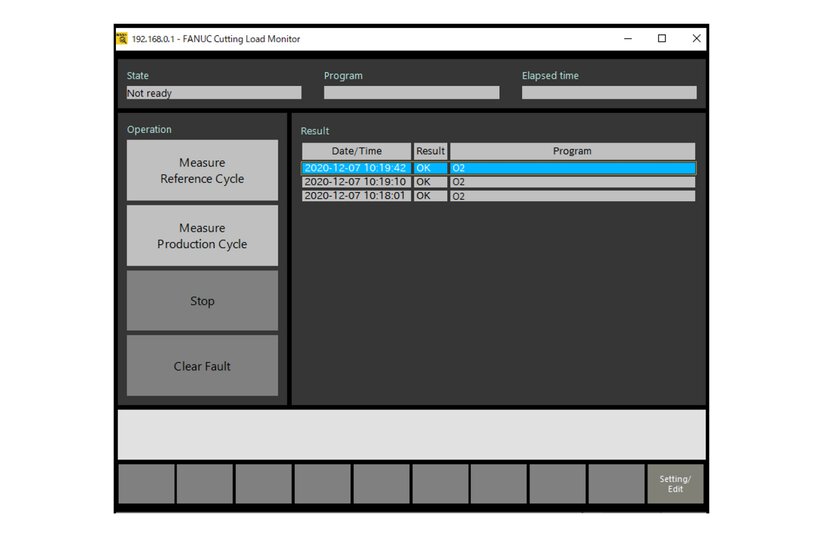

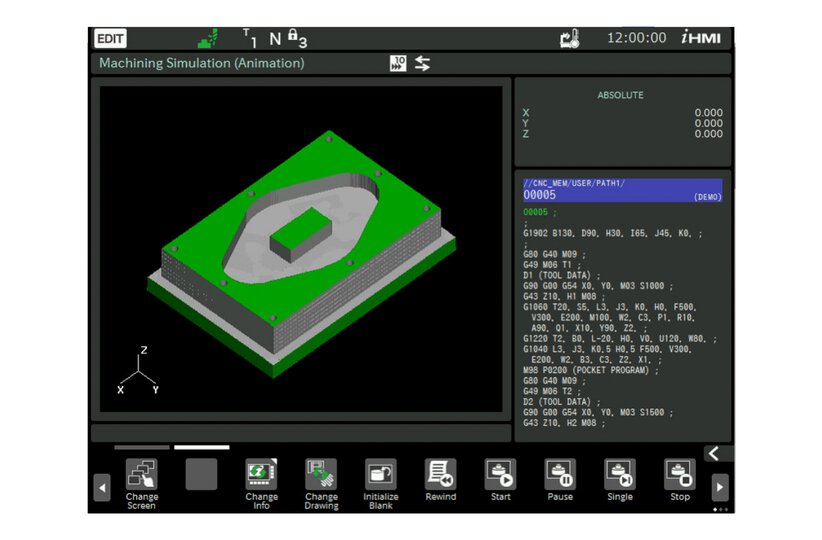

High Speed Drilling and Tapping

Elevate Your Machining with FANUC

High-speed drilling and tapping offer several advantages. With advanced spindles and rapid tool changers, these processes ensure quick transitions between operations, leading to significantly reduced cycle times and increased throughput. Their versatility allows them to handle a wide range of tasks, making them ideal for maximising efficiency in compact spaces.

Get Inspired

Get Inspiration from Other's Success

Vedos Achieves Precision with FANUC ROBODRILL

When it comes to finding the right balance between high-precision, efficiency and cost, precision component manufacturer Vedos relies on FANUC’s ROBODRILL milling centers.

A Good Grip on Machining: ROBODRILL Provides Six-fold Increase in Capacity

With rising global demand for robots, Grip GmbH needed more machining centre capacity to enhance productivity and reduce costs. They chose FANUC's advanced ROBODRILL 𝛼-D21M𝑖B5ADV machining centres, known for speed, precision, reliability, and flexibility, even for single component lots. These machines, featuring a FANUC robot and an innovative tool and workpiece handling system, enable unmanned production of small series and individual parts. This solution boosted Grip GmbH's machining capacity nearly six-fold.

EUROEDIL Enjoys Faster Cutting Rates and Higher Throughput with FANUC Machines

With its new FANUC machines in-site, EUROEDIL has increased its cutting rate and throughput to meet rising volume demands from customers. Moreover, the accuracy and precision of the company’s die-cutting tools have improved noticeably.

Transform your Industry with FANUC ROBODRILL

Automotive

Aerospace

Electronics

Medical

Plastics

Electric Vehicles

All Industries

Our Solutions for Other Applications

Boost Efficiency, Precision, and Productivity with FANUC's Solutions for Different Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.