- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

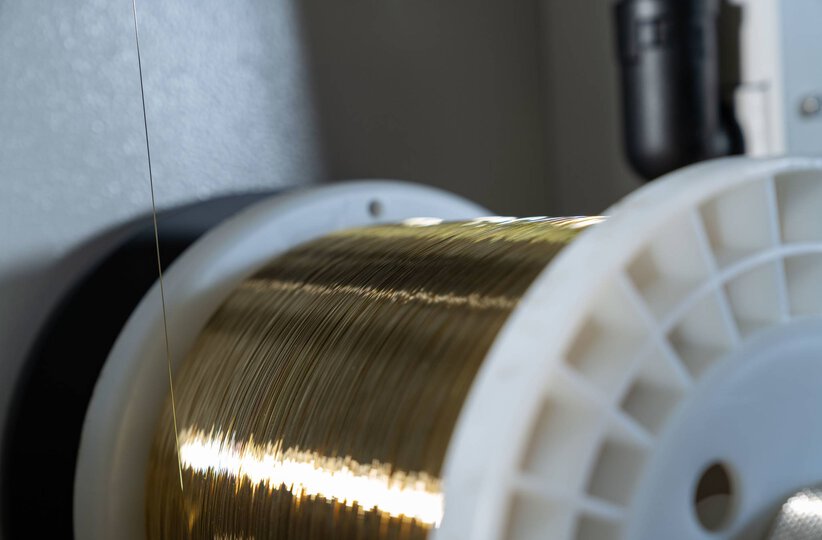

Wire Cutting EDM

Elevate Your Wire Cutting EDM with FANUC Solutions

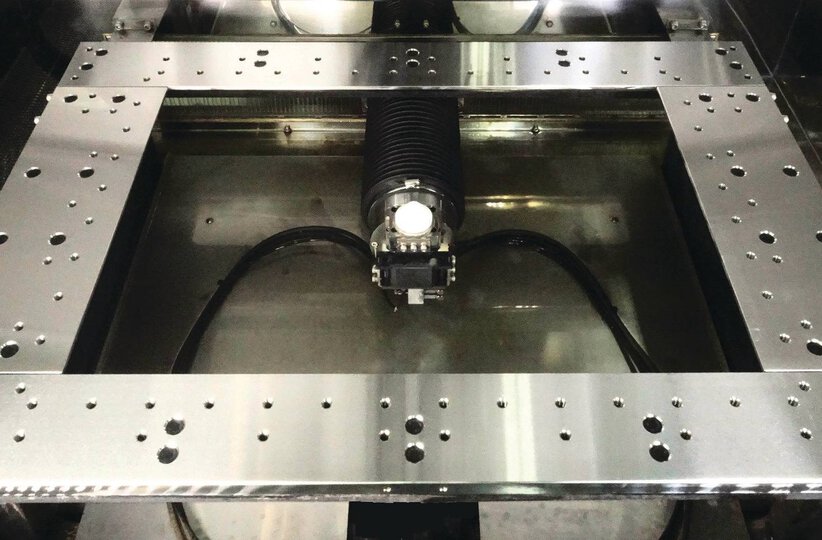

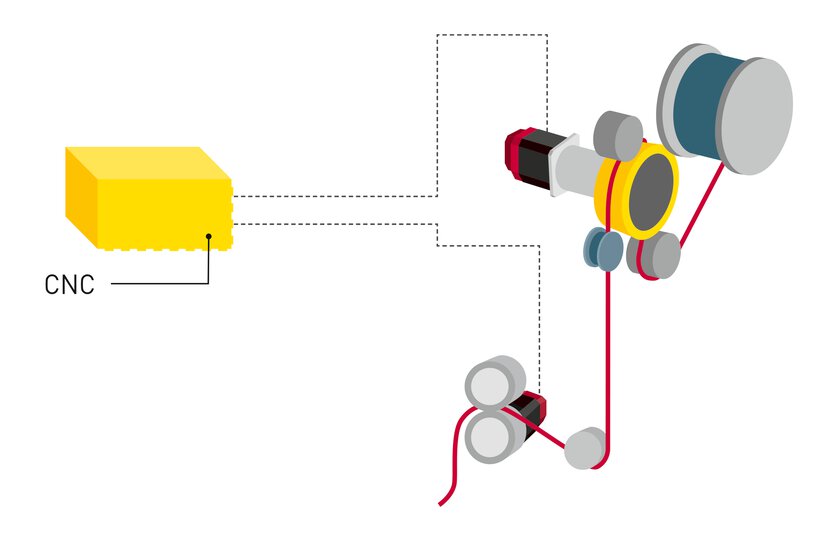

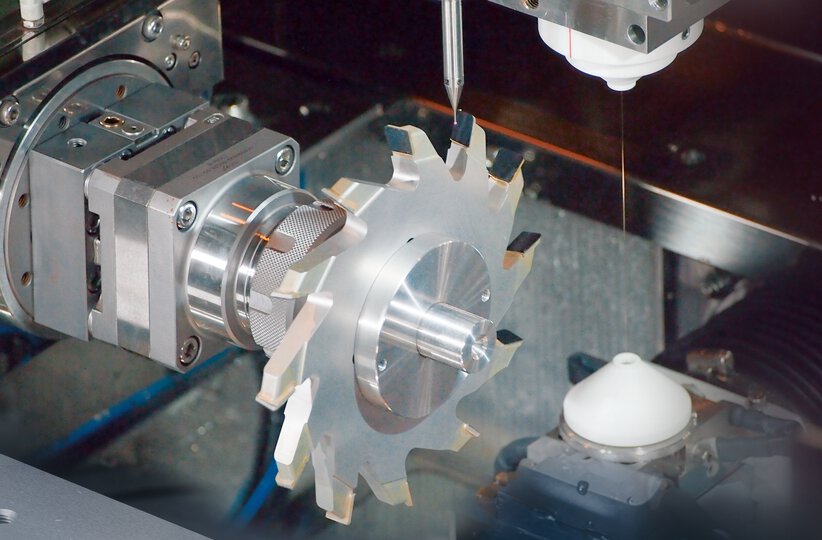

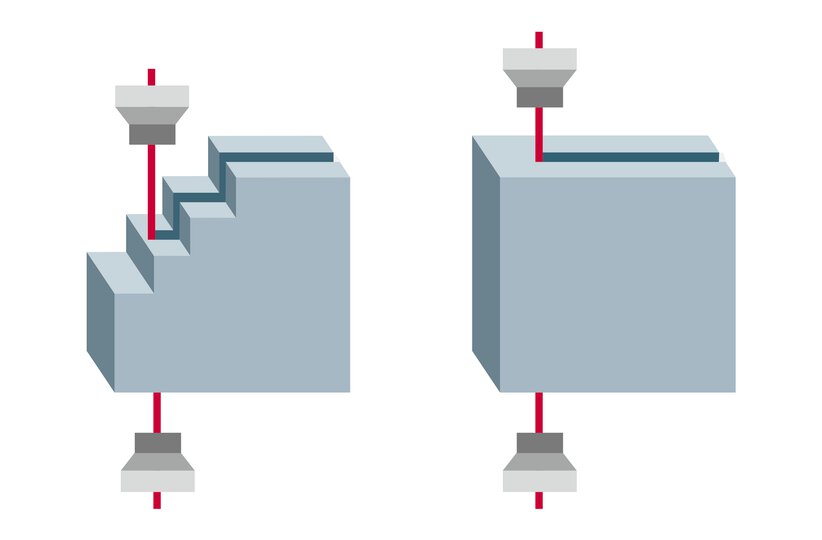

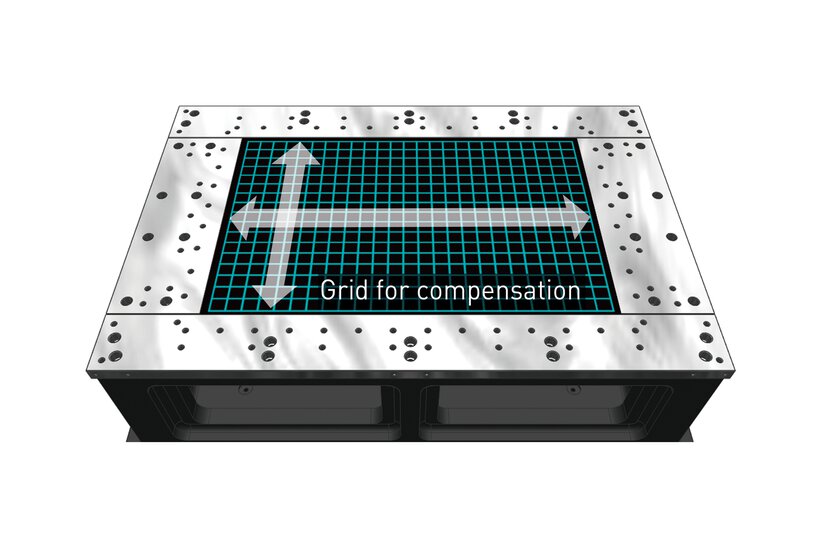

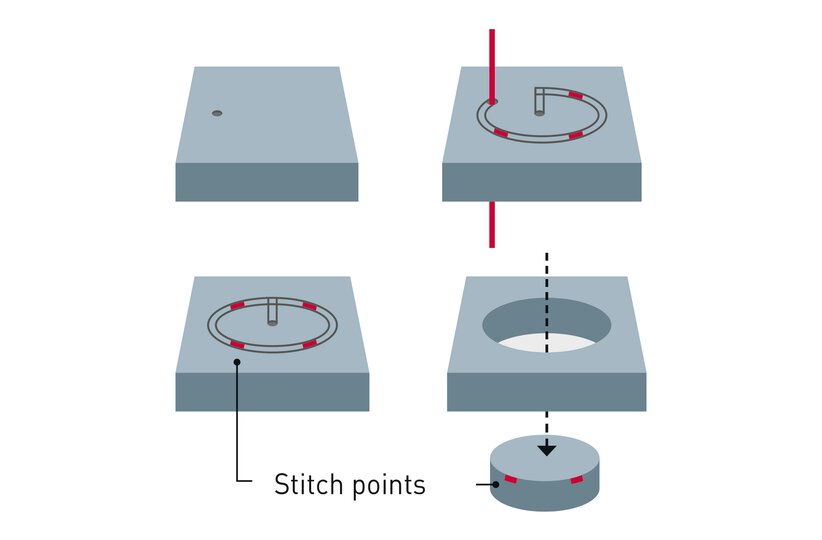

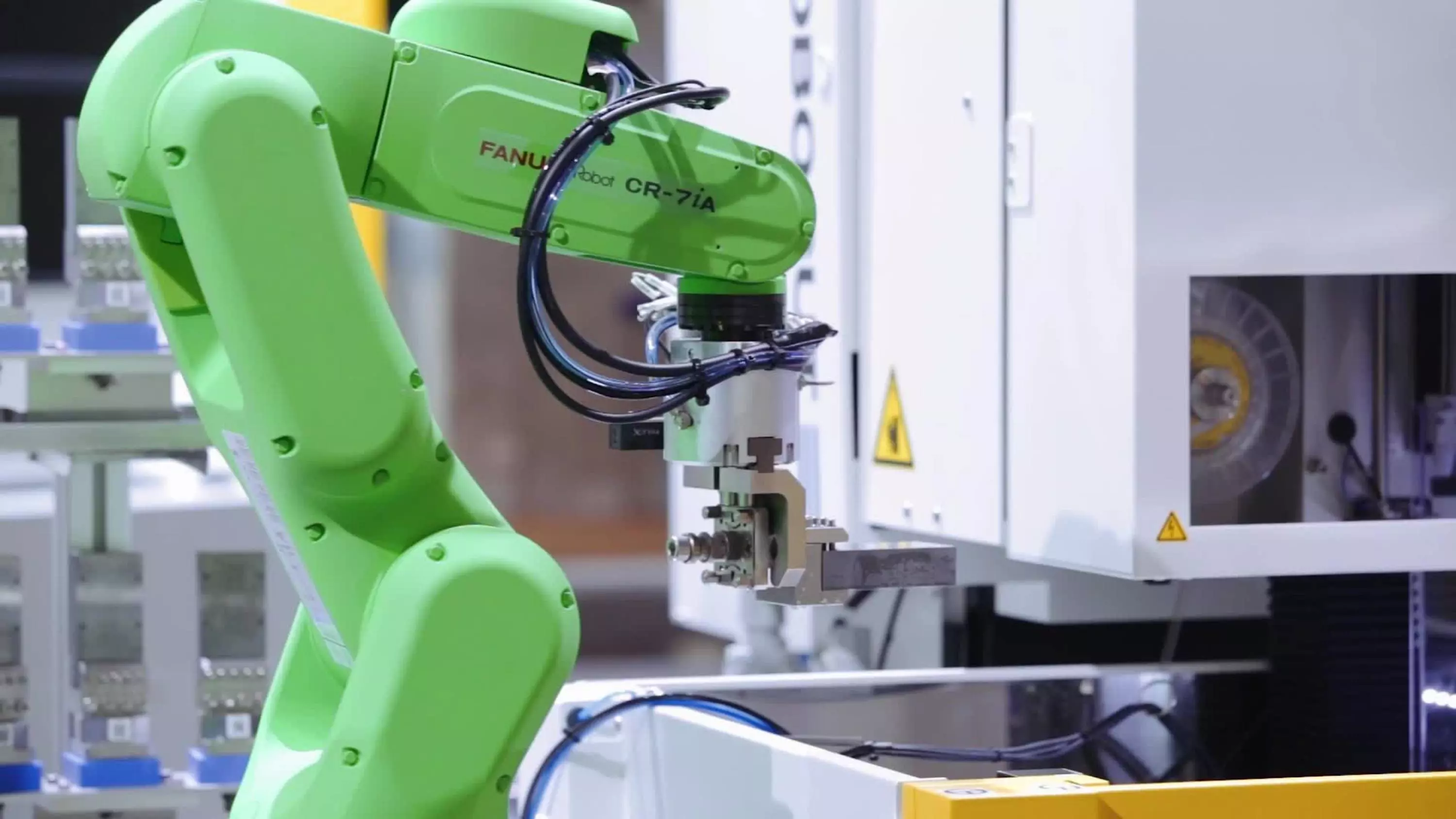

Our FANUC ROBOCUT Wire EDM machines set the standard for precision, reliability, and efficiency in the most demanding cutting tasks. Engineered with advanced technology and FANUC’s renowned expertise, our ROBOCUT delivers consistent, high-quality results across industries such as aerospace, medical device manufacturing, and automotive. With user-friendly controls and superior accuracy, ROBOCUT is the ideal choice for achieving precise, reliable performance in your Wire EDM applications.

Get Inspired

Get Inspiration from Other's Success

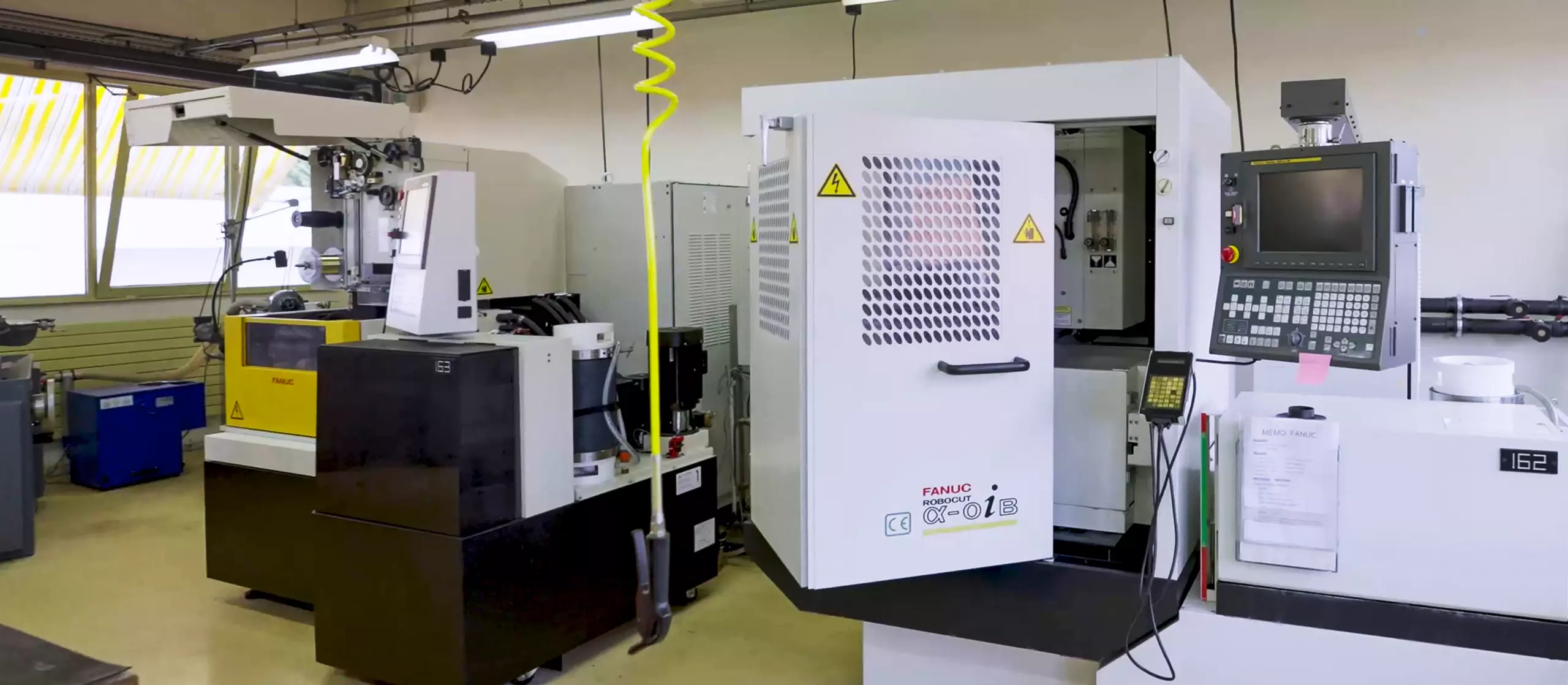

FANUC ROBOCUT Machines Underpin Success at Leading Injection Mould Manufacturer

Haidlmair, a top injection mould specialist, invested in two more FANUC ROBOCUT wire EDM machines, continuing a decades-long partnership and legacy of precision.

FANUC Solutions Provide Common Thread at Screw-Cutting Specialist

Moving from labour-based to automated production operations can sometimes appear daunting. And yet, with the right technology partner on-board, processes such as automated machining and assembly can come to realisation with relative ease, instantly delivering new levels of productivity and reliability.

EUROEDIL Enjoys Faster Cutting Rates and Higher Throughput with FANUC Machines

With its new FANUC machines in-site, EUROEDIL has increased its cutting rate and throughput to meet rising volume demands from customers. Moreover, the accuracy and precision of the company’s die-cutting tools have improved noticeably.

Powder Metallurgy Specialist Enjoys Dusting of FANUC Excellence

Where a new manufacturer quickly achieves success, it becomes necessary to find a suitable partner for factory automation. Selecting the optimal supplier will help the manufacturer to ramp-up quickly in line with growing customer demand, while simultaneously facilitating higher levels of productivity and efficiency.

Transform your Industry with FANUC Wire Cutting EDM Solutions

Automotive

Aerospace

Electronics

Medical

Plastics

All Industries

Learn More about our Infinite Possibilities

Our Solutions for Other Applications

Boost Efficiency, Precision, and Productivity with FANUC's Solutions for Different Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.