- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

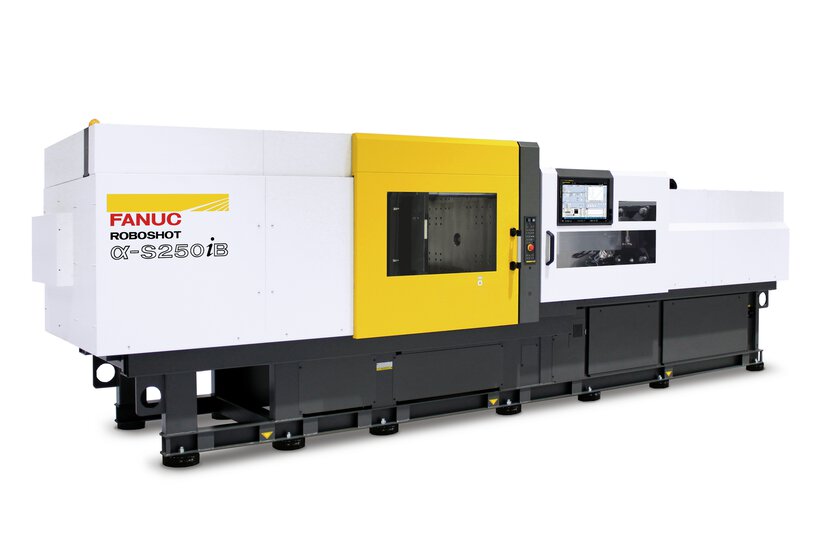

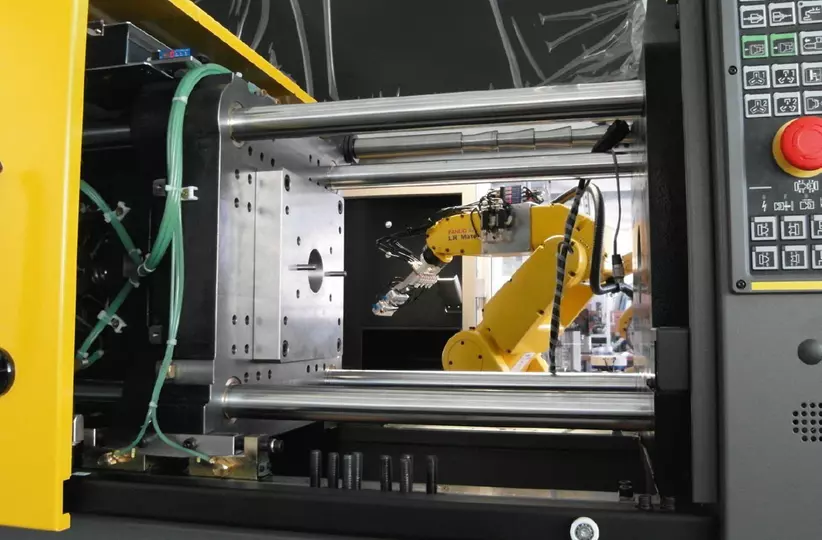

Injection Moulding

The Main Advantages of Electrical Injection Moulding

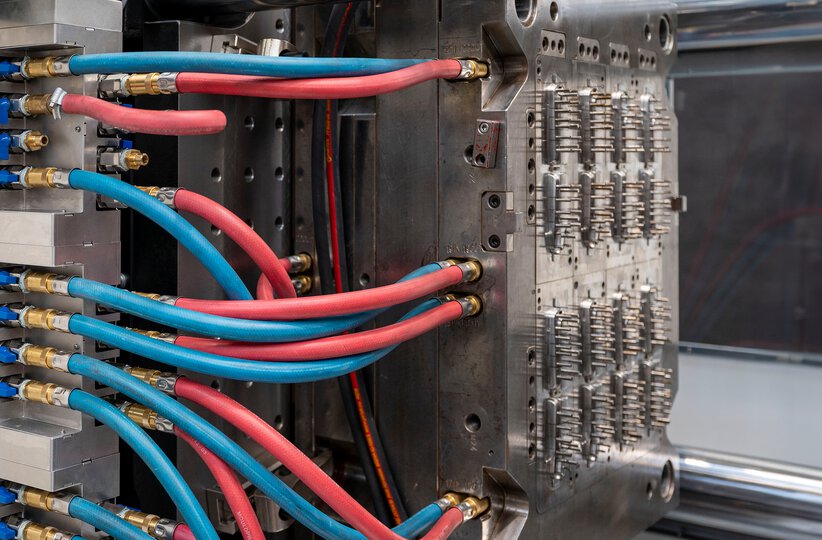

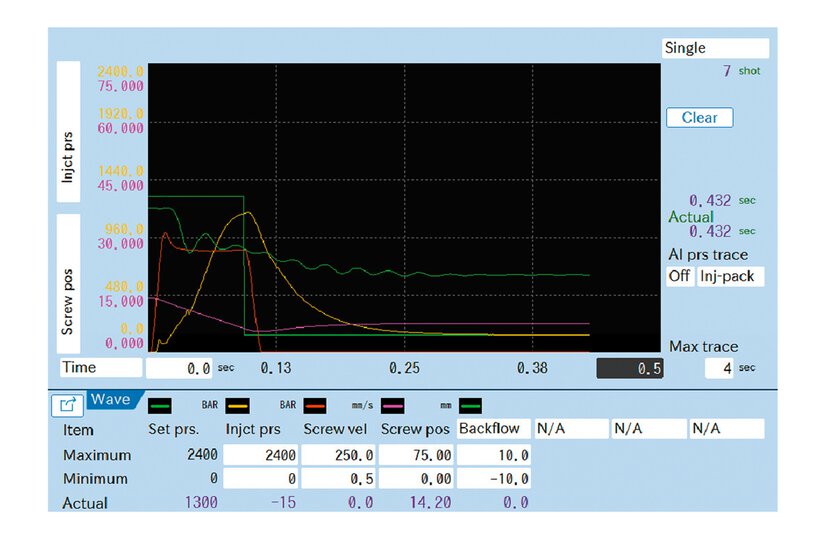

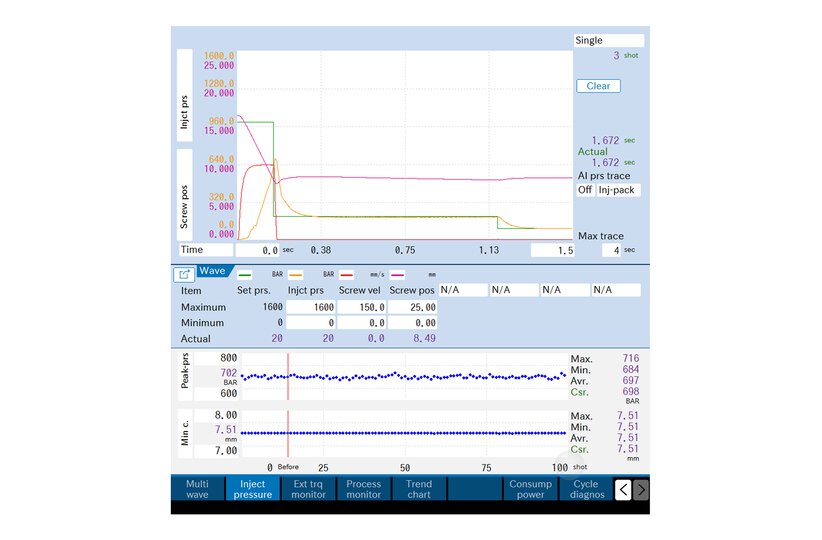

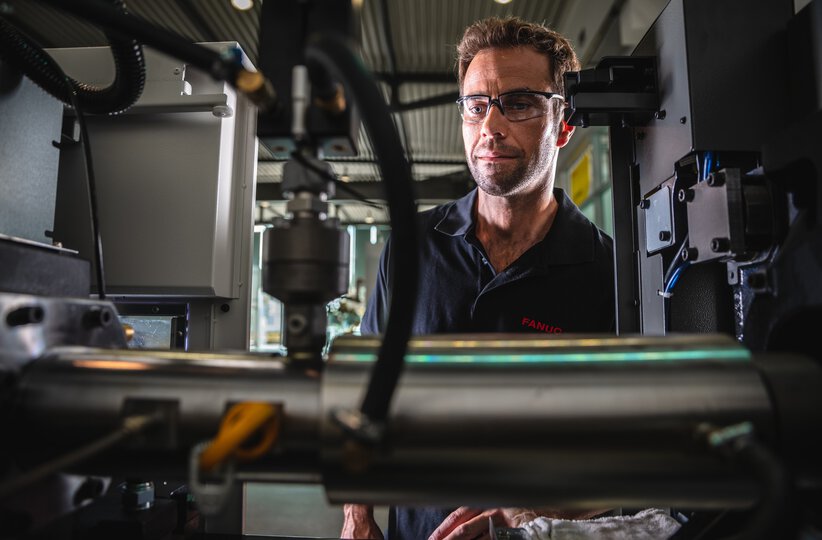

When it comes to the injection moulding process, consistency, repeatability and accuracy represent key criteria for most manufacturers. Electric injection moulding machines excel in this regard. More stable than hydraulic machines, they provide the ability to achieve precision moulding using consistent sets of parameters which, once set, are monitored and controlled by the machine. Ensuring improved parts quality, these machines achieve the same high-quality results every time and, given greatly reduced manual input, also benefit from improved uptimes and cycle times. In addition to these advantages, good electric injection moulding machines offer a range of additional features and benefits that make them more efficient still.

Get Inspired

Get Inspiration from Other's Success

TESY on the Road to Efficiency With ROBOSHOT

High production efficiency, low energy costs and noise emissions bundled with great technical support and service is what customers can expect from FANUC’s ROBOSHOT fully electric injection moulding machine.

FANUC ROBOSHOT Machines Keep Things Simple for SIMON

High-volume plastics parts; thin walls; zero defects; short automotive lead times; demanding energy efficiency requirements. A growing number of manufacturers are combatting these common challenges by investing in ROBOSHOT high-performance, all-electric injection moulding machines from FANUC. Among their number is SIMON Plastics.

Transform your Industry with FANUC ROBOSHOT

Automotive

Aerospace

Electronics

Plastics

Electric Vehicles

All Industries

Our Solutions for Other Applications

Boost Efficiency, Precision, and Productivity with FANUC's Solutions for Different Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.